|

|||

|

|

|||

|

Page Title:

HEMTT CREW PROTECTION ARMOR KIT INSTALLATION |

|

||

| ||||||||||

|

|

II106700-5

Rev. B

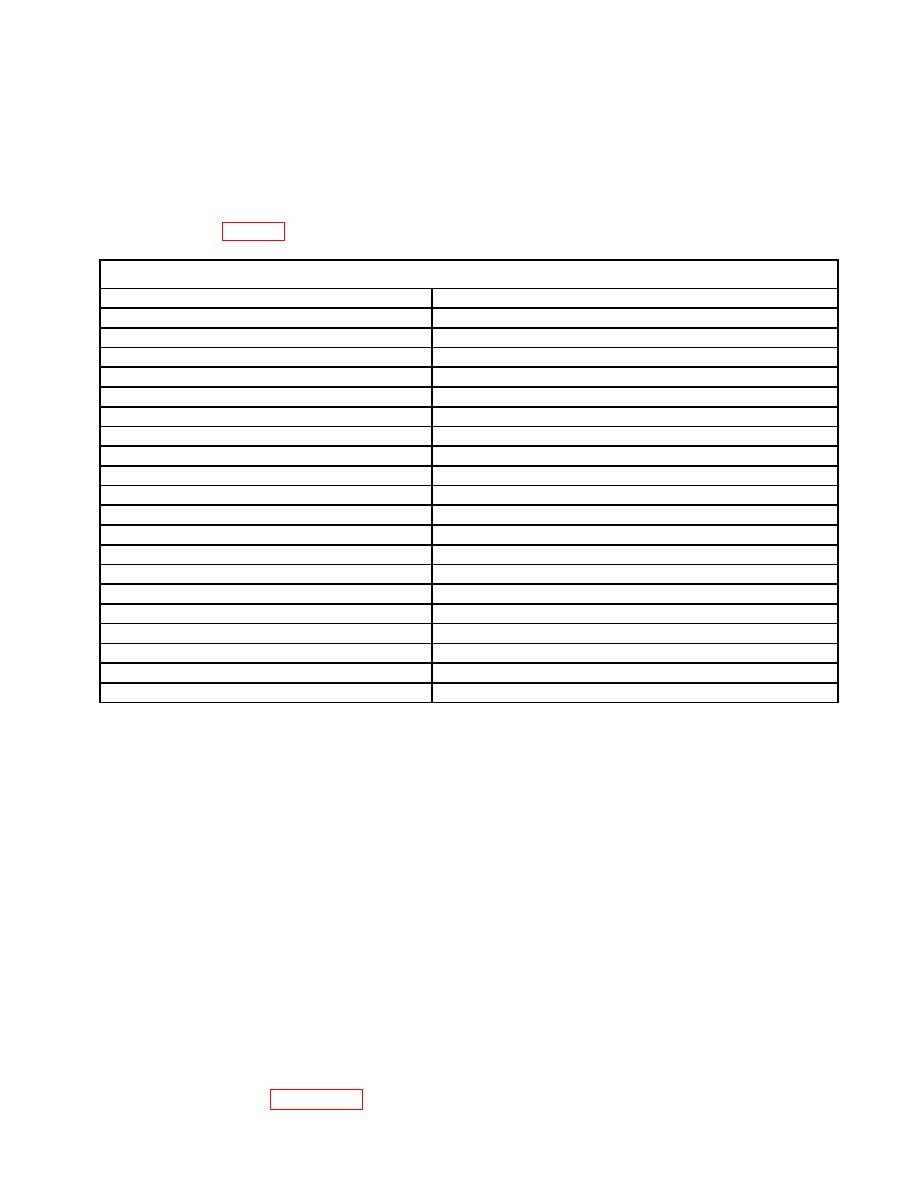

4.1 EQUIPMENT AND MATERIALS

The equipment and materials required to install the Crew Protection Armor Kit onto the HEMTT

are provided in Table 2.

Description

Part Number

Automotive General Mechanics Tool Kit

SC5180-90-N26

2.5-Ton Floor Jack

Commercially Available

8-in. C-Clamps

Commercially Available

Fork Lift / Overhead Hoist

Commercially Available

1/2-in. Drill

Commercially Available

1/2-in. Right-Angle Drill

Commercially Available

3/16-, 1/4-, 7/16-, 9/16-, 17/32-in. Drill Bits

Commercially Available

3/8-in. Drill Bit

Commercially Available

1/2-in., 5/8-in. Drill Bits

Commercially Available

Loctite 242 (Blue)

Commercially Available

Wire Ties

Commercially Available

Caulking Gun

Commercially Available

Lift Straps

Commercially Available

3/8-in.-Drive 0-90 ft-lb Torque Wrench

Commercially Available

1/2-in.-Drive 0-150 ft-lb Torque Wrench

Commercially Available

3/4-in.-Drive 0-280 ft-lb Torque Wrench

Commercially Available

5/16-in. 18 Rivnut Installation Tool

AKPT518TAK or equivalent - Commercially Available

3/8-in. 16 Rivnut Installation Tool

AKPT616TAK or equivalent - Commercially Available

1/4-in. 3/4-in. Uni-Bit

Commercially Available

#50 Torx Socket

Commercially Available

NOTE

These Installation Instructions will provide the illustration directly after that

installation callout, and the text will be on either the same page or the facing

page, where practical. All necessary information, torque values, tool numbers,

and materials used will be provided so that the unit can be assembled without

reference to another part of the installation instructions. Prior to installation,

check the envelope on the back cover for any supplemental instructions.

Any variant configurations may require alternate fastener lengths. These

fasteners are found in the Extra Fastener Kit, P/N 111444.

a. Before beginning the assembly of a part, remove all corrosion-preventative

compound (if any) and any accumulated foreign matter.

b. All nuts, bolts, and screws used in the installation of the Kit must be coated with

Loctite 242 thread lock adhesive and tightened to standard torque values, unless

otherwise stated. The locknuts supplied with the Kits do not require Loctite 242.

A list of standard thread / pitch sizes and the corresponding torque values are

provided in Appendix A.

0039 00-31

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |