|

| |

TM 9-2320-364-20-2

2-1073

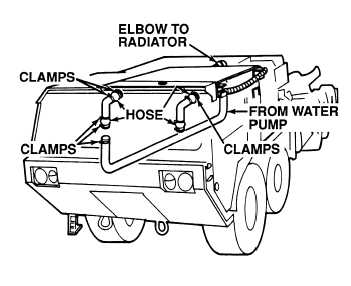

(1) Using hose diagram (Para 6-8), check

coolant hoses for leaks, cracks, and

bulging.

(2) Check for loose or damaged clamps.

(3) Look for wet spots, drips, and stains

that indicate where coolant is leaking.

(a) If you see cracked hoses or loose,

damaged clamps, tighten or

replace clamps or replace hoses

(Para 6-8).

(b) If no leaks or damage is observed,

hoses and clamps are OK.

HOSE INSPECTION

Allow engine to cool before performing troubleshooting maintenance. If necessary use insulated pads

and gloves. Hot engine components will burn and cause injury to personnel.

Pressure loss without external leaks indicates

internal coolant leaks.

NOTE

|