|

| |

TM 9-2320-364-20-3

2-2186

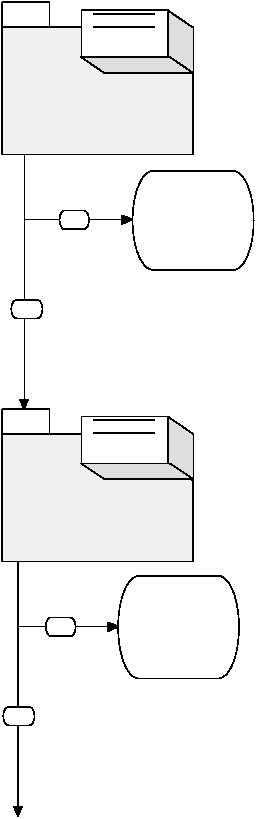

1. AIR PRESSURE BUILDUP IS SLOW (CONT).

2.

Are purge valves on air dryers

and aftercooler free of leaks

or damage?

Replace purge

valve(s)

(Para 12-21 and

12-22).

Verify repair, go to

Step 9 of this Fault.

YES

NO

Air cleaner OK.

Air dryer filters OK.

Coalescing filter OK.

Aftercooler filter OK.

Drain valves OK.

Leaking air dryer and

aftercooler purge valves.

Restricted air compressor inlet

air line.

Leaking or restricted

compressor discharge air line.

Leaking check valves.

Damaged air compressor.

Damaged air governor.

Air dryer or aftercooler check

valves faulty.

KNOWN INFO

POSSIBLE PROBLEMS

TEST OPTIONS

REASON FOR QUESTION

Visual inspection.

Audible inspection.

Air pressure buildup will be slow

if air is continually leaking from

air dryer or aftercooler purge

valves.

3.

Is air line 2600 free of

damage, crimps or leaks and

are fittings free of leaks?

Tighten loose

fittings or replace air

line 2600 (Para 12-36

and schematic

Fig 2-50).

Verify repair,

go to Step 9 of

this Fault.

YES

NO

Air cleaner OK.

Air dryer filters OK.

Coalescing filter OK.

Aftercooler filter OK.

Drain valves OK.

Air dryer and aftercooler purge

valves OK.

Restricted air compressor inlet

air line.

Leaking or restricted

compressor discharge air line.

Leaking check valves.

Damaged air compressor.

Damaged air governor.

Air dryer or aftercooler check

valves faulty.

KNOWN INFO

POSSIBLE PROBLEMS

TEST OPTIONS

REASON FOR QUESTION

Visual inspection.

Audible inspection.

Air will not flow freely to air

compressor if air compressor

inlet air line 2600 is leaking,

crimped or damaged.

WARNING

WARNING

Read WARNING

on Page 2-2187

Read WARNING

on Page 2-2187

|