|

| |

TM 9-2320-364-20-3

2-2193

Allow engine to cool before performing troubleshooting maintenance. If necessary use insulated pads

and gloves. Hot engine components will burn and cause injury to personnel.

Wear safety goggles when performing tests on valves. Failure to do so may result in serious eye injury

due to high pressure air.

(1) Drain air system (TM 9-2320-364-10).

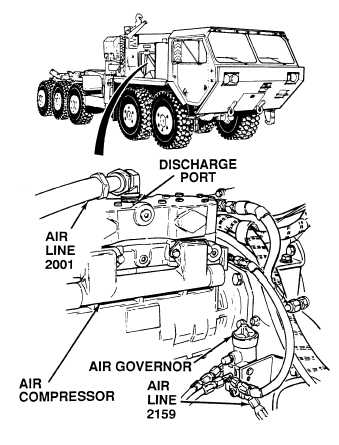

(2) Disconnect governor control

air line 2159 from air governor.

(3) Disconnect air compressor discharge

air line 2001 from air compressor.

(4) While assistant starts engine,

listen to air compressor discharge

port.

(a) If little or no air flows from

discharge port, perform Steps (5)

through (7) below, and notify DS

maintenance.

(b) If air flows freely from discharge

port, air compressor is OK.

(5) Turn OFF ENGINE switch.

(6) Install air compressor discharge

air line 2001 on air compressor.

(7) Install governor control air line 2159

on air governor.

AUDIBLE INSPECTION

|