|

| |

TM 9-2320-364-20-3

2-2211

Allow engine to cool before performing troubleshooting maintenance. If necessary use insulated pads

and gloves. Hot engine components will burn and cause injury to personnel.

Wear safety goggles when performing leakage tests

on valves. Failure to do so may result in

serious eye injury due to high pressure air.

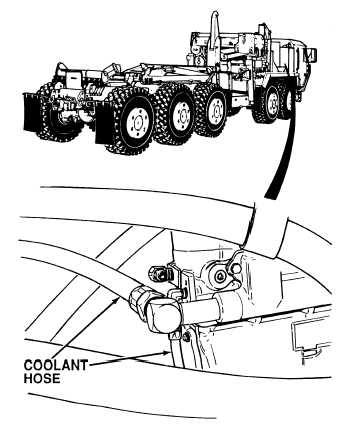

Check air compressor coolant hoses and

fittings for leaks or damage.

(1) If hoses are leaking or damaged,

tighten fittings, repair or replace

coolant hoses (Para 6-8).

(2) If hoses are not leaking or damaged,

go to Step 3 of this Fault.

VISUAL INSPECTION

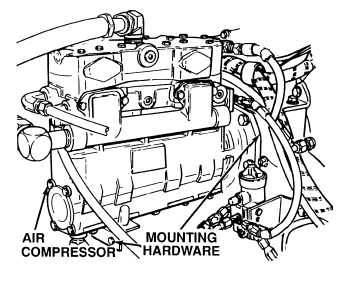

(1) Check air compressor for damage and

loose or damaged mounting

hardware.

(a) If compressor is cracked, leaking,

or seized, notify DS Maintenance.

(b) If compressor mounting is loose,

notify DS Maintenance.

(c) If compressor is securely mounted

and not damaged, go to Step 4 of

this Fault.

(2) Install right side noise panel

(Para 17-26).

VISUAL INSPECTION

|