|

| |

TM 9-2320-364-20-4

7-22

7-5. ALTERNATOR BELTS REPLACEMENT/ADJUSTMENT (200 AMP) (CONT).

Adhesive causes immediate

bonding on contact with eyes,

skin, or clothing and also gives

off harmful vapors. Wear

protective goggles and use in

well-ventilated area. If adhesive

gets in eyes, try to keep eyes

open; flush eyes with water for

15 minutes and get immediate

medical attention.

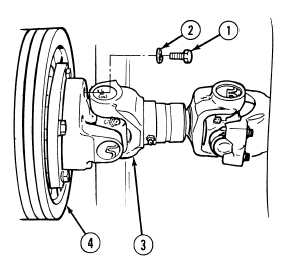

(7)

Coat threads of four screws (1) with sealing

compound.

(8)

Install pump drive shaft assembly (3) on

engine (4) with four lockwashers (2) and

screws (1). Tighten screws to 60 lb-ft (81

N.m).

c.

Adjustment.

NOTE

If adjusting only, perform Steps

(2) through (6) of a. Removal

and Steps (2) through (6) of b.

Installation.

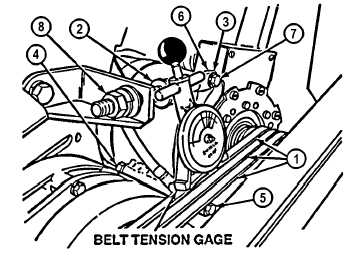

(1)

Install belt tension gage on one belt (1).

(2)

Tighten nut (2) on alternator support arm (3)

until alternator belt tension reaches 60 to 65

lbs (260-289 N). Check tension on other

two belts.

(3)

Tighten nut (4) on screw (5) to 90 lb-ft (122

N.m).

(4)

Tighten locknut (6) on screw (7) to 26 to 30

lb-ft (30 to 41 N.m).

(5)

Tighten nut (8) on alternator support arm

(3).

(6)

Remove belt tension gage from alternator

belt (1).

|