|

| |

TM 9-2320-364-20-4

10-10

10-2. DRIVESHAFT AND UNIVERSAL JOINT REPAIR (CONT).

e.

Installation.

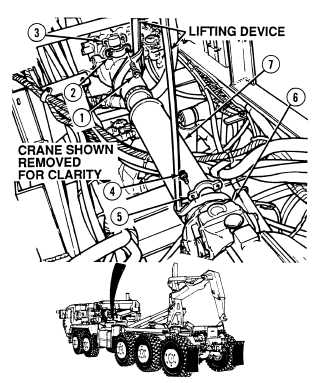

Driveshafts can weigh up to 100 lbs (45 kg), obtain aid from an assistant to prevent

possible injury to personnel.

Adhesive causes immediate bonding on contact with eyes, skin, or clothing and also gives

off harmful vapors. Wear protective goggles and use in a well-ventilated area. If adhesive

gets in eyes, flush with water for 15 minutes

NOTE

Driveshafts are properly

installed when yoke is facing

towards power source.

(1)

With the aid of an assistant, position and

extend driveshaft (7) into yokes (4) and (6).

(2)

Coat threads of four screws (4) with sealing

compound.

(3)

Install four screws (4) and two bearing

straps (5) to yoke (6). Refer to Table 10-3

for proper torque and tighten screws.

(4)

Coat threads of four screws (1) with sealing

compound.

(5)

Install four screws (1) and two bearing

straps (2) to yoke (3). Refer to Table 10-3

for proper torque and tighten screws.

Table 10-3. Bearing Strap Screw Torque Requirements

Driveshaft

Torque Requirement

Axle No. 1 to Axle No. 2

55 to 60 lb-ft (75 to 81 N.m)

Axle No. 2 to Transfer Case

130 to 135 lb-ft (176 to 183 N.m)

Transfer Case to Axle No. 3

130 to 135 lb-ft (176 to 183 N.m)

Axle No. 3 to Axle No. 4

130 to 135 lb-ft (176 to 183 N.m)

Axle No. 4 to Axle No. 5

55 to 60 lb-ft (75 to 81 N.m)

Transmission to Transfer Case

130 to 135 lb-ft (176 to 183 N.m)

f.

Follow-On Maintenance:

Lubricate driveshaft and universal joint, (Para 2-22).

LHS in transit position, (TM 9-2320-364-10).

Remove wheel chocks, (TM 9-2320-364-10).

END OF TASK

|