|

| |

TM 9-2320-364-20-5

14-6

14-3. STEERING TOE-IN ADJUSTMENT (CONT).

NOTE

Toe-in is determined by subtracting distance A from distance B. Proper toe-in

should be 1/8 in. (1.6 mm) to 1/16 in. (1.6 mm) toe-in (B A = toe in).

If your toe-in reading is more than 1/8 in. (1.6 mm) to 1/16 in. (1.6 mm), check the

tie-rod measurement.

Tie-rods on Axle No. 1, 2 and 5 when measured from grease fitting to grease fitting should

be within the limits shown in Table 14-1.

Table 14-1. Tie-Rod Acceptable Starting Measurements

Tie-Rod

Measurement

Axle No. 1

56-5/8 in. ( 1/8 in.)

Axle No. 2

54-9/16 in. ( 1/8 in.)

Axle No. 5

51-9/16 in. ( 1/8 in.)

(6)

Determine toe-in (B A = toe-in).

NOTE

If distance is correct, toe-in

adjustment is complete: go to

Step (18). If distance is not

correct, continue with Step (7).

(7)

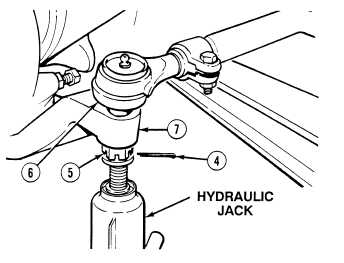

Remove cotter pin (4) and loosen castle

nut (5) even with bottom of stud on tie-rod

end (6). Discard cotter pin.

Tie-rod end may unexpectedly

pop-up when pressure is applied

with hydraulic jack. Keep hands

and face clear of tie-rod end.

Failure to comply may result in

severe injury to personnel.

(8)

Using hydraulic jack, press tie-rod end (6)

loose from steering arm (7).

|