|

| |

TM 9-2320-364-34-4

20-225

(14)

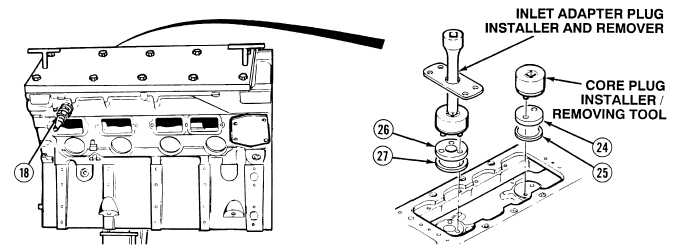

Using installer/remover, install gasket (25) and core plug (24). Tighten core plug 230 to 270 lb-ft (312 to

366 N.m).

Be careful when using high air pressure. Ensure connections and seals are tight before

applying pressure. High air pressure can blow out parts, hoses or debris with force.

Explosive force can damage equipment and cause injury to personnel.

(15)

Apply 40 psi (276 kPa) pressure to engine block (5) through fitting (18). Maintain pressure for at least

two hours.

(16)

Inspect engine block (5) for leaking antifreeze. If leaks are found, engine block (5) must be replaced.

(17)

Slowly relieve 40 psi (276 kPa) pressure from engine block (5).

(18)

Remove air line and air adapter fitting (18) from engine block (5).

(19)

Drain antifreeze from engine block (5).

(20)

Remove core plug and gasket.

(21)

Coat threads of water inlet adapter (26) with sealing compound.

(22)

Using remover/installer, install gasket (27) and water inlet adapter (26) in engine block (5). Tighten

water inlet adapter (26) to 230 to 270 lb-ft (312 to 366 N.m).

|