|

| |

TM 9-2320-364-34-4

20-228

Materials/Parts

Compound, International, No. 2

(Item 16, Appendix B)

Oil, Lubricating (Item 36, Appendix B)

Plastigage (Item 44, Appendix B)

Bearing Set (5) (Item 12, Appendix E)

Lockscrew (7) (Item 223, Appendix E)

Washer, Thrust (4) (Item 698, Appendix E)

This task covers:

a. Installation

b. Follow-On Maintenance

INITIAL SETUP

Personnel Required

Two

Equipment Condition

Engine cylinder block repaired, (Para 20-64)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Indicator, Dial, Set w/Magnetic Base

(Item 98, Appendix F)

Wrench Set, Socket 3/4 in. Drive

(Item 274, Appendix F)

Wrench, Torque (0 to 175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

Wrench, Torque (0 to 600 lb-ft [0-814 N.m])

(Item 278, Appendix F)

Lifting Device, Minimum Capacity 400 lbs

(182 kg)

20-65. MAIN BEARING AND CRANKSHAFT INSTALLATION.

a.

Installation.

Do not handle bearing shells and thrust washers more than necessary for installation.

Sweat from hands can damage bearing shells and thrust washers. Make sure bearing shells

and thrust washers are clean before installation.

Main bearings are a matched set and cannot be interchanged or damage to equipment may

result.

Upper bearing shells have a through - slot for lubrication. Incorrect installation of bearing

shells will result in damage to equipment.

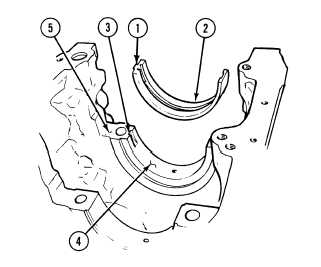

NOTE

Bearing surfaces are numbered

one to five from front to rear of

engine block.

(1)

Align tab (1) on upper bearing shell (2) with

slot (3) on engine block bearing surface (4).

(2)

Install shell (2) on bearing mounting

surface (5). Make sure both ends of shell are

flush with bearing cap mounting surfaces (5).

(3)

Repeat Steps (1) and (2) for four other

bearing surfaces.

(4)

Apply lubricating oil to upper bearing

shells (2) after installation.

|