|

| |

TM 9-2320-364-34-4

20-238

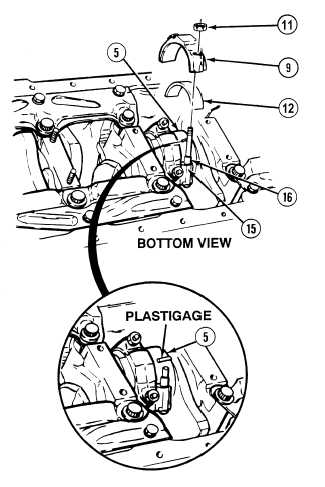

20-67. PISTON, CONNECTING ROD AND LINER INSTALLATION (CONT).

(21)

Seat connecting rod (15) firmly on

crankshaft journal (5).

(22)

Wipe oil from bearing shells (12) and

crankshaft journals (5).

(23)

Place strip of plastic gage across width of

bearing shell (12) 1/4 in. (6.35 mm) from

center.

(24)

Install bearing shell (12) and cap (9) over

two screws (16).

(25)

Install two nuts (11) and tighten 60 to 70

lb-ft (81 to 95 N.m).

(26)

Remove two nuts (11) from screws (16).

(27)

Remove cap (9) from screws (16).

NOTE

Width must be minimum of

0.0008 in. (0.0203 mm) and

maximum of 0.0056 in. (0.1422

mm). If measurement cannot be

obtained, replace upper and

lower bearing shells.

(28)

Measure widest part of plastic gage with

measuring strip.

(29)

Wipe plastic gage from bearing shells (12)

and crankshaft journals (5) and coat with

lubricating oil.

(30)

Install bearing shell (12) and cap (9) over

two screws (16).

(31)

Install two nuts (11) and tighten 60 to 70

lb-ft (81 to 95 N.m).

|