|

| |

TM 9-2320-364-34-4

21-34

21-3. TURBOCHARGER ASSEMBLY REPAIR (CONT).

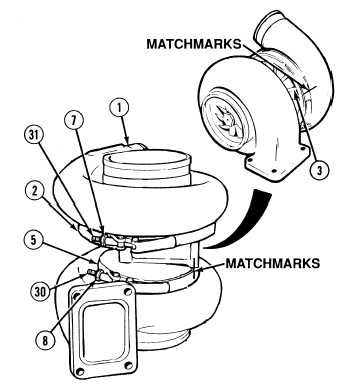

(35)

Loosen locknut (8) on clamp (5) and

retighten to 50 lb-in (6 N.m).

(36)

Tighten locknut (8) on clamp (5) to 165

lb-in (18.9 N.m).

(37)

Install clamp (2) over center housing (6).

(38)

Align matchmarks on turbo housing (1) and

backplate (3) and install turbo housing (1)

on backplate (3).

(39)

Apply lubricating oil to threads of

screw (31).

(40)

Tighten locknut (7) on screw (31) to 110 to

130 lb-in (12 to 15 N.m).

(41)

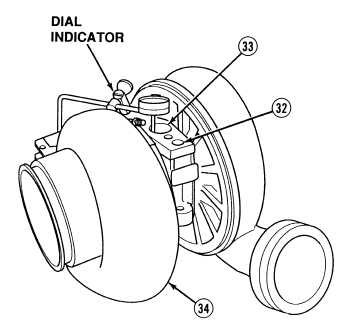

Position dial indicator with magnetic base

swivel adapter and extension rod, on flat

surface of housing inlet flange (32).

NOTE

Do not allow extension rod to

touch sides of center housing.

Inaccurate readings can result in

poor fit and damage.

(42)

Position extension rod in oil drain hole (33)

so rod is against turbine wheel shaft.

NOTE

Disassemble and inspect

turbocharger if fit of turbine

wheel shaft is not within limits.

(43)

Ensure turbine wheel shaft moves up and

down not more than 0.0070 in. (0.177 mm)

or less than 0.003 in. (0.076 mm).

END OF TASK

|