|

| |

TM 9-2320-364-34-4

25-52

Materials/Parts

Grease (Item 22, Appendix B)

Solvent, Drycleaning (Item 68, Appendix B)

Wire, Nonelectrical (Item 79, Appendix B)

Cross (2) (Item 38, Appendix E)

Fitting, Grease (4) (Item 50, Appendix E)

Sealing Kit (Item 623, Appendix E)

This task covers:

a. Removal

c. Installation

b. Cleaning/Inspection

d. Follow-On Maintenance

INITIAL SETUP

Personnel Required

Two

Equipment Condition

Axle No. 1, 2 and 5 pivot and spindle/trunnion

bearing assembly removed, (Para 25-12)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Extractor, Inertial (Item 56, Appendix F)

Extractor, Inertial (Item 57, Appendix F)

Gloves, Chemical Oil Protective

(Item 81, Appendix F)

Goggles, Industrial (Item 83, Appendix F)

Pliers, Retaining Ring (Item 158, Appendix F)

Press, 60 Ton (Item 164, Appendix F)

Puller Kit, Universal, Slide Hammer

(Item 175, Appendix F)

Removal Tool, Bearing Cap, Constant Velocity

U-Joint (Appendix C)

25-13. AXLE NO. 1, 2 AND 5 CONSTANT VELOCITY JOINT REPAIR.

a.

Removal.

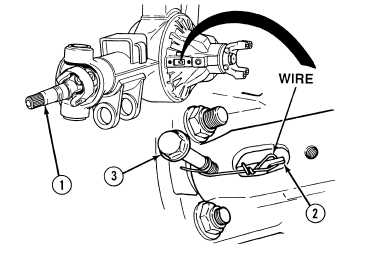

The following step keeps clutch gear from disengaging after constant velocity shaft are

removed. Failure to perform step makes assembly difficult and could damage parts.

NOTE

Screw used in Step (1) is from locking cylinder.

Step (1) is for left side constant velocity joint removal on Axle No. 1 and 5 only.

Step (1) is for right side constant velocity joint for Axle No. 2 only.

Axle No. 1 is shown in illustration. Axles No. 2 and 5 are similar.

Axles No. 1, 2 and 5 constant

velocity shafts are removed the

same.

Clutch collar is engaged when

both constant velocity shafts turn

in the same direction when axle

yoke is turned.

(1)

With the aid of an assistant, engage clutch

collar by turning constant velocity shafts (1)

slowly, while pulling outward on fork (2).

(2)

Form a wire hook around fingers of fork (2)

and anchor with screw (3).

|