|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-385-14

b.

Cleaning/Inspection.

(1)

Inspect bearing parts for corrosion or damage. Replace all parts that are corroded or damaged.

Drycleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles, face

shield, and gloves; use only in a well-ventilated area; avoid contact with skin, eyes, and

clothes, and do not breathe vapors. Keep away from heat or flame. Never smoke when

using solvent; the flashpoint for Type II Drycleaning Solvent is 140 degrees F (60 degrees C)

and Type III Drycleaning Solvent is 200 degrees F (93 degrees C). Failure to do so may

result in injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts

eyes, immediately flush eyes with water and get immediate medical attention.

Do not use compressed air to clean bearings. Bearings can come apart causing injury or death

to personnel.

(2)

Clean all bearing parts with drycleaning solvent and allow to air dry.

(3)

Clean inside and outside of spindle with drycleaning solvent. Ensure 1/32 in. (.8 mm) hole inside center

of spindle is not plugged. Drill 1/32 in. (.8 mm) hole if hole is not present.

c.

Installation.

NOTE

If studs were removed, perform Step (1).

(1)

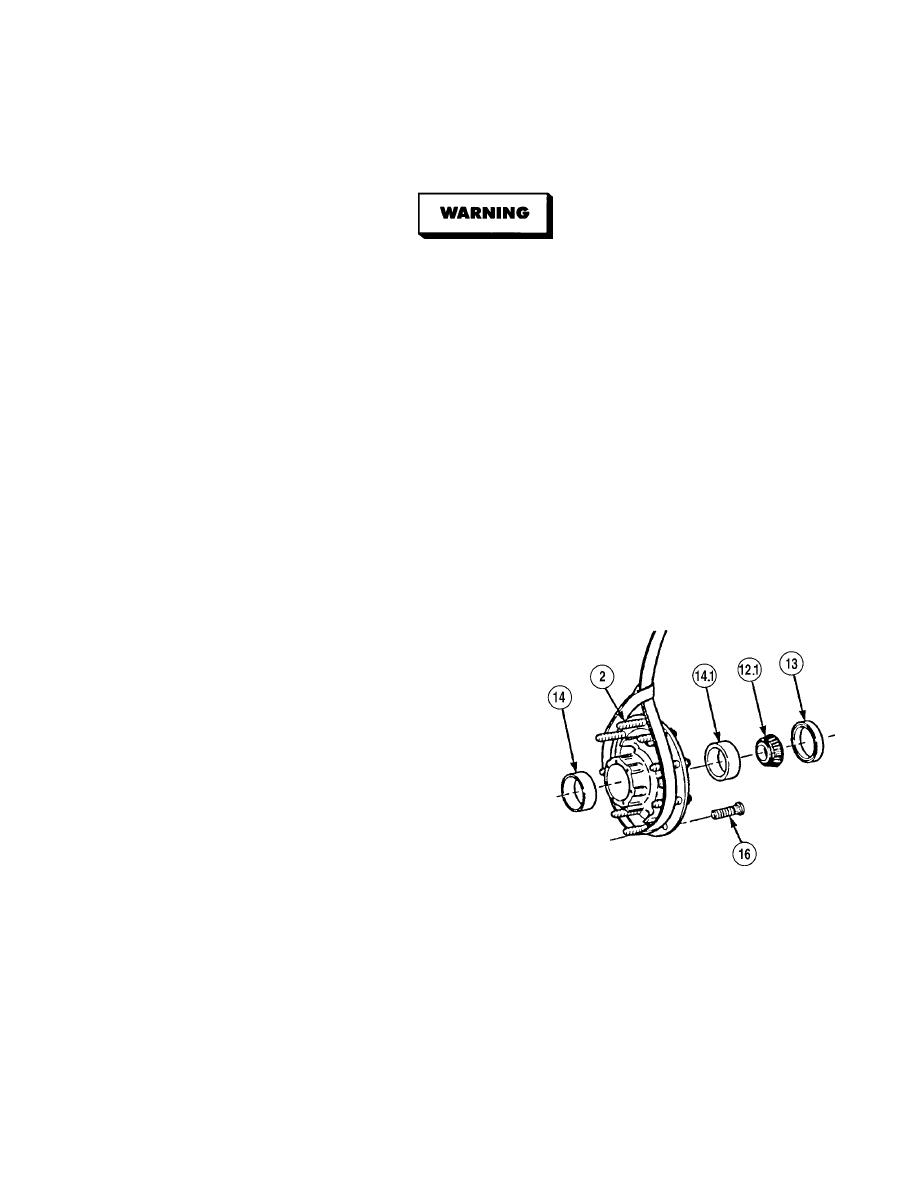

Install stud (16) in hub (2) until base of stud is

seated against back edge of hub.

(2)

Apply light film of grease on inside of

hub (2) and on bearing cups (14) and (14.1).

(3)

Install bearing cups (14) and (14.1) in hub

(2).

(4)

Pack area of hub (2) between bearing cups

(14) and (14.1) with grease up to smallest

diameter of bearing cups.

NOTE

Perform Steps (5) and (6) for hub mounted

seals.

(5)

Pack inner bearing (12.1) with grease and

install in hub (2).

NOTE

The wider edge of seal goes on hub first.

(6)

Install seal (13) in hub (2).

4-521

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |