|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-385-14

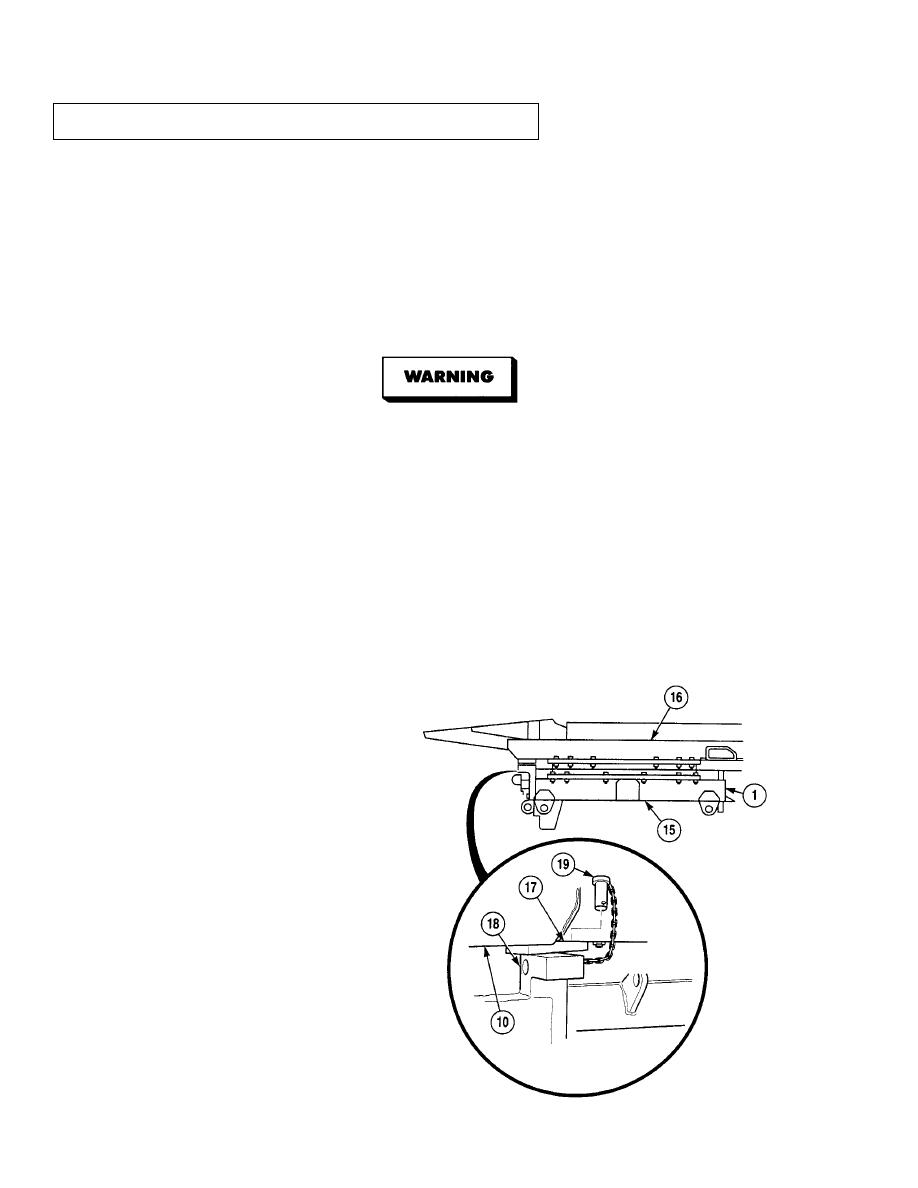

6-8. TURNTABLE/BEARING REPLACEMENT (CONT).

NOTE

If a new turntable is being installed, perform Steps (13) through (18). If the original

turntable is to be installed, perform Steps (13) through (15).

(13)

Rotate turntable (1) until the left and right side members (15) of turntable are aligned with frame main

rails (16).

(14)

Align upper locking plate (17) and lower locking plate (18).

(15)

Insert locking pin (19) through upper locking plate (17) and lower locking plate (18).

CARC paint contains isocyanate (HDI) which is highly irritating to skin and respiratory

system. High concentrations of HDI can produce symptoms of itching and reddening of

skin, a burning sensation in throat and nose and watering of the eyes. In extreme

concentrations, HDI can cause cough, shortness of breath, pain during respiration,

increased sputum production and chest tightness. The following precautions must be

taken whenever using CARC paint:

-

-

NEVER weld or cut CARC-coated materials.

Unsafe welding practices can cause serious injury from fire, explosions, or harmful agents.

Allow only authorized personnel to weld or cut metals and follow safety precautions

TC 9-237. Protective clothing and goggles must be worn; adequate protective equipment

used and suitable fire extinguisher kit near by; and requirements of TC 9-237 strictly

followed.

NOTE

If the left and right side

members of turntable do not

align with frame main rails when

the locking pin is installed

perform Steps (16) and (17). If

frame main rails and left and

right side members align, go to

Step (19).

(16)

Using a wire brush, remove CARC paint

from area four in. (102 mm) around

welding/grinding points.

(17)

Grind off welds from upper locking plate

(17) on trailer frame (10) and remove

locking plate from frame.

(18)

Refer to TC 9-237 and tack weld upper

locking plate (17) in place.

6-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |