|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-3990-206-14&P

Do the SEMIANNUAL PREVENTIVE MAINTENANCE (Table 4-1) once every six months.

a.

b. Always do the Preventive Maintenance in the same order until it gets to be a habit. Once practiced, it will be

easy to spot anything wrong in a hurry.

If anything looks wrong and is not fixed, write a DA Form 2404.

c.

d. When doing Preventive Maintenance, take along the tools and supplies needed to make all the checks,

including a clean cloth or two.

The following is a breakdown of the PMCS table:

e.

(1)

"Item No." column. Checks and services are numbered in a logical order for moving around the flatrack.

The item number column is used as a source of items numbers for the TM Number Column on DA Form

2404, Equipment Inspection and Maintenance Worksheet, for recording results of the PMCS.

(2)

"Interval" column. The column identifies when the PMCS should be performed.

(3)

"Item To Check/Service" column. This column identifies the item to be checked/serviced.

(4)

"Procedure" column. This column contains all the information required to do the check/inspection.

(5)

"Not Mission Capable If:" column. This column contains a brief statement of the condition (e.g.,

malfunction, shortage) that would cause the flatrack to be less than fully ready to perform its assigned

mission.

Location

Item to

Interval

Procedure

Not Fully Mission

Item

Check/Service

Capable If:

No.

Semi-

Flatrack Floor

Visually check flatrack floor for

1

Annually

corrosion, dirt, oil and damage.

Semi-

Flatrack

Visually inspect all weldments for cracks

2

Weldments

Annually

and other damage. Report damage to

supervisor.

Semi-

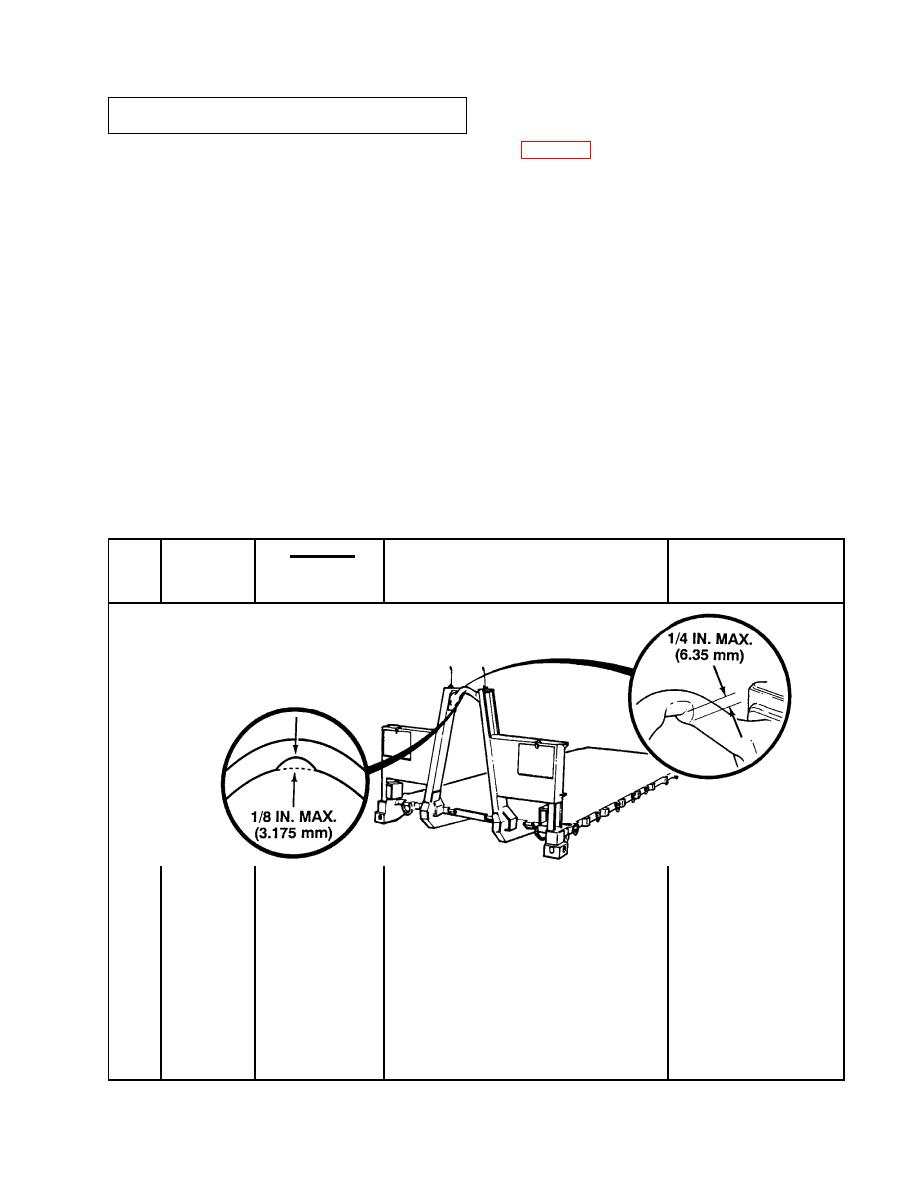

Hook Bar

Check hook bar for wear. If wear at lower

Wear at lower back side

3

Annually

back side of hook bar is greater than 1/4

of hook bar is greater

in. (6.35 mm) or greater than 1/8 in.

than 1/4 in. (6.35 mm) or

(3.175 mm) at bottom of hook bar, notify

greater than 1/8 in.

supervisor.

(3.175 mm) at bottom of

hook bar.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |