|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-3990-206-14&P

Section III. UNIT MAINTENANCE PREVENTIVE MAINTENANCE CHECKS AND

SERVICES (PMCS)

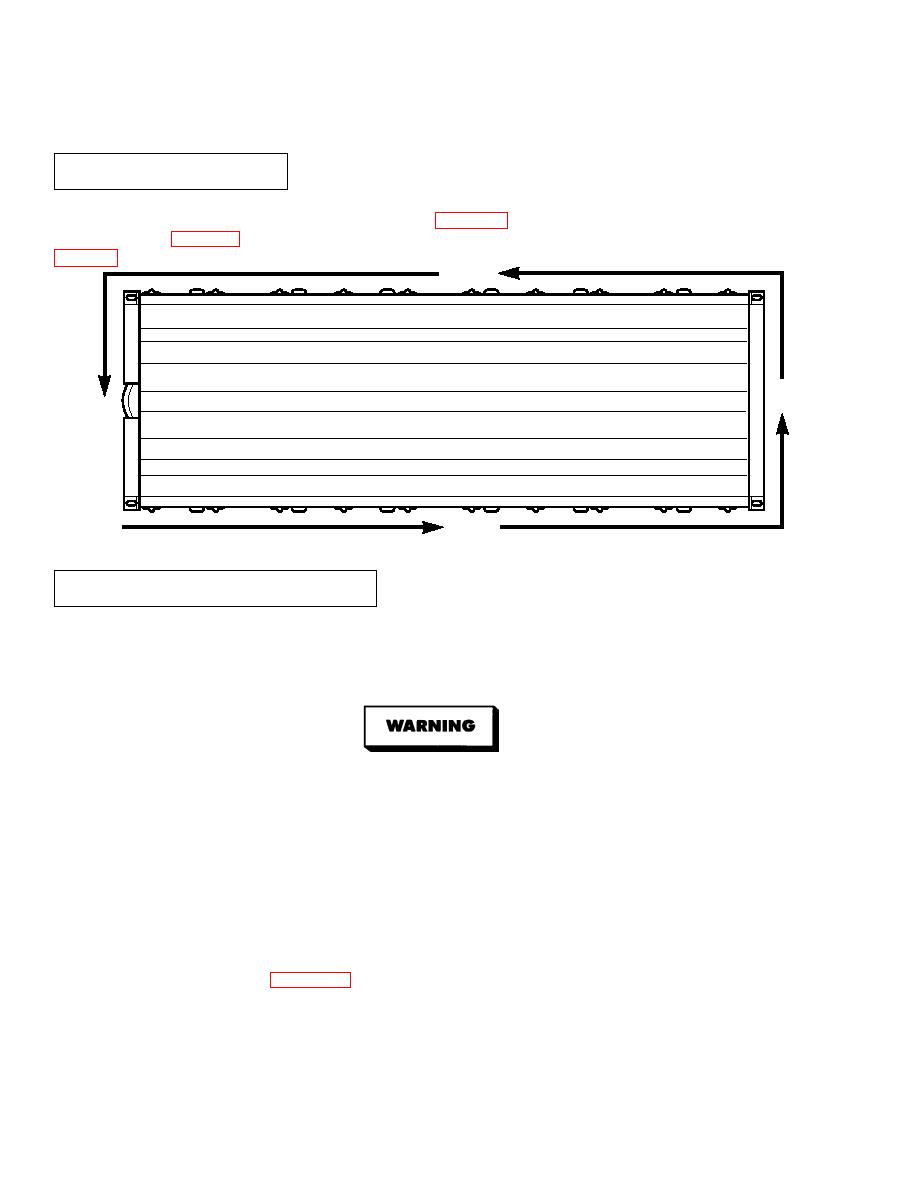

This section presents Unit Maintenance checks and services. Figure 9-1 illustrates the route to use in completing the

PMCS procedures. Table 9-1 provides PMCS procedures. Unit Maintenance should also perform Operator PMCS

START

a. Always perform your preventive maintenance in the same order, so it gets to be a habit. Once you have

some practice, you will spot anything wrong in a hurry.

If something looks wrong and you can not fix it, write it down on DA Form 2404.

b.

Drycleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles, face

shield, and gloves; use only in a well-ventilated area; avoid contact with skin, eyes, and

clothes, and do not breathe vapors. Keep away from heat or flame. Never smoke when

using solvent; the flashpoint for Type II Drycleaning Solvent is 140 degrees F (60 degrees C)

and Type III Drycleaning Solvent is 200 degrees F (93 degrees C). Failure to do so may

result in injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts

eyes, immediately flush eyes with water and get immediate medical attention.

c. Clean as you work and as needed. Dirt, grease, oil and debris may get in the way and cover up a problem.

Use drycleaning solvent (Item 14, Appendix E) to clean flatrack where dirt, grease or oil has accumulated.

d. Check for missing, loose, bent or broken bolts, nuts and screws. Look for chipped paint, bare metal or rust

around bolt heads. Tighten loose parts.

e. Look for loose paint, rust or gaps where parts are welded together. If you find a bad weld, report it to

Direct Support Maintenance.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |