|

| |

(2-32)

Preparing PLS for CONTAINER MODE.

1)

a

Stow straps securing LF to truck.

b

Rotate flipper brackets to attach LF to LHS;

Pull flipper lock pin handle and actuate air valve.

2)

Do other side (Straps and flipper bracket).

3)

Deploy LH slider.

4)

Deploy RH slider.

5)

Cycle LHS to unload so LF is 1 foot off the ground’

AUTO mode till LHS stops, then switch to MANual HA.

6)

Deploy LF strut leg, pin using second hole from the bottom.

7)

Pin flipper bracket lock plates open, RH&LH.

8)

Cycle LHS to unload to unhook LF from LHS, until LHS stops.

Use manual hook arm mode to fully extend arm.

9)

Drive straight ahead about 1 foot.

10) a

Rotate LH bumper supports rearward into Container position.

b

Remove LH guide from stowed position on truck.

c

Install guide on LH slider.

11) Do other side (rubber bumper and guide).

12) Install Transit Lock in ready mode on sliders, LH & RH.

13) Cycle LHS to load so hook arm is at correct height for hooking

onto the bail bar, using manual HA mode.

14) SWITCH LHS to AUTO mode.

15) Cycle LHS to load to pick up LF 1 foot.

16) Attach bail bar lock to Hook Arm to secure LF.

17) Stow LF strut leg.

18) Configure LF for container to be transported.

Proper hook in slide arms, slide arm un–pinned as needed.

19) Cycle LHS to load to secure LF before operating truck.

(2-38)

Returning PLS to FLATRACK MODE

1)

Verify LF is not locked to HA.

2)

Cycle LHS to unload so LF is 1 foot off the ground.

2)

a

Remove guide from Slider.

b

Install pins in guide.

c

Stow guide in stow bracket and pin.

d

Rotate bumper support forward to stow.

3)

Do other side (guide and bumper).

4)

Deploy LF strut leg, using second hole from bottom.

5)

Remove Bail Bar Lock from Hook Arm and stow.

6)

Cycle LHS to unload to unhook LHS from LF, using auto mode,

drive ahead about 1 foot.

7)

Remove transit locks from sliders and stow locks on LF, do both

RH & LH.

8)

Remove pins and secure LF slide arms RH&LH.

9)

Stow LH slider.

10) Stow RH slider.

11) Verify flipper brackets are rotated out.

12) Unlock Flipper bracket lock plates RH&LH, rotating handle until

held up in notch.

13) Cycle LHS to unload to fully extend LHS, in auto mode

LHS pivot pin should be below flipper bracket.

14) Back up until contact LF with Hook Arm, LHS pin should be

positioned to engage Flipper brackets.

15) Cycle LHS to load to pick LF up 1 foot.

16) Verify LF flipper bracket lock plates have locked around LHS

pivot pin.

17) Lock LF flipper bracket lock plates by rotating pin handle 180

from notch position, both RH and LH sides.

18) Stow LF strut leg.

19) Verify paddles are proper fore/aft position to engage LF.

Check (LF locked to LHS, slide arms pinned, bumpers forward,

transit locks stowed, paddles straight).

20)

Cycle LHS to load until LF is in stowed position.

20) a

Rotate flipper brackets to detach LF from LHS;

pull flipper lock pin handle and actuate air valve.

b

Secure LF strap to truck.

21) Do other side (Flipper bracket and strap).

LOADING Container

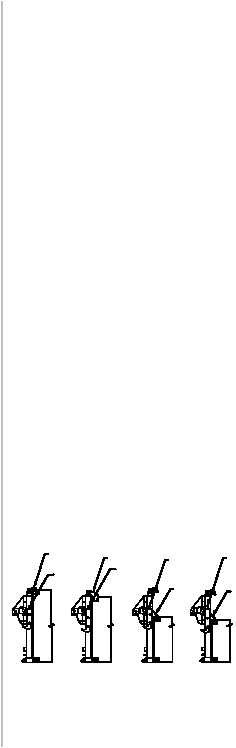

(2-33) 6 foot 10 in. or higher, (2-34) 6 foot, (2-35) 4 foot 3 in., (2-36) 4 foot

(CHECKS: Lower Locks unlocked, LF configured for size container

Bumper supports rearward, slider and transit locks ready).

1)

Verify that LF is not locked to HA and truck is in container mode.

2)

Back up to container to within 9’. Align truck with container.

3)

Cycle LHS to unload until LF upper hooks are visible just below top

edge of container.

4)

Ensure LF configured for container,

Slide arms pinned if needed,

Lower container locks unlocked,

Correct hook in slide arm.

5)

Back truck up until LF contacts container. Aligning hooks with

container corner openings.

6)

Cycle LHS to load until hooks are above container.

7)

Continue backing up truck until hooks positioned over container.

8)

Cycle LHS to unload to engage hooks into container top corners.

9)

Continue to cycle LHS until lower locks are low enough to engage

container bottom corners.

10) Back up truck to engage LF lower locks in container corners.

Steer truck to align lower locks with container.

(CHECK: Upper hook thumb engaged, lower locks flush,

Sliders positioned straight ahead & clean of debris).

11) Lock lower locks to container; handle straight up, lock plate

over handle and handnut.

12) Lock other side.

13) Cycle LHS to load to lift container onto truck.

14) Observe clearance between container and slider guides on both

sides to ensure container centered during loading.

15) Fully load container until LHS not transit light goes out.

16) Pin transit locks in locked position, RH & LH.

17) Verify container is properly loaded onto the truck.

UNLOADING container

(2-33) 6 foot 10 in. or higher, (2-34) 6 foot, (2-35) 4 foot 3 in., (2-37) 4 foot

(CHECKS: LF properly attached to container,

Container loaded properly).

1)

Verify sufficient room & ground conditions.

2)

Disengage transit locks, RH & LH,

Lock transit locks in ready position.

3)

Cycle LHS to unload to unload container.

4)

Unlock lower container locks; handle inward,

handnut tightened up, lock plate over handnut.

5)

Unlock other side.

6)

Drive forward approximately 6”, to disengage lower locks.

7)

Cycle LHS to load to disengage upper hooks from container.

8)

Continue to cycle LHS fully to load until LHS no transit light

goes out, CHU in ready mode.

STANDARD

HOOK

(6’10”, 8’, 8’6”)

NO PIN

INSTALLED

6’ HOOK

PIN

INSTALLED

NO PIN

INSTALLED

HALF

HEIGHT

HOOK

PIN

INSTALLED

HALF

HEIGHT

HOOK

6’10”

OR TALLER

6’ TALL

4’3” TALL

4’ TALL

FOLD

FOLD

TM 9-2320-364-10

2-671

|