|

| |

TM 9-2320-364-20-2

2-1783

Truck must be on level ground and wheels

must be chocked before parking brake is

released. Otherwise, truck may roll and

cause injury to personnel.

Wear safety goggles when performing leakage

tests on valves. Failure to do so may

result in serious eye injury due to high

pressure air.

If air lines are under high pressure when

they are disconnected, they can whip around

and cause injury to personnel. Caution

should be exercised when loosening or

disconnecting air line fittings.

(1) Start engine and build pressure

to 125 4 psi (861 28 kPa)

(TM 9-2320-364-10).

(2) Turn OFF ENGINE switch.

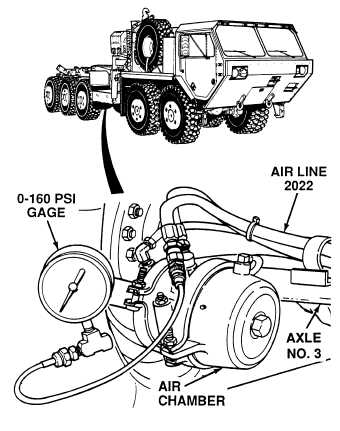

(3) Disconnect air line 2022 from right

air chamber on Axle No. 3.

(4) Connect a 0 to 160 psi (0 to 1103 kPa)

gage to air line 2022.

(5) Release and apply PARKING BRAKE.

(a) If there are 125 4 psi

(861 28 kPa) present at air line

2022, perform Steps (6) and (7)

below and replace relay spring

valve No. 1 (Para 12-16).

(b) If there are not 125 4 psi

(861 28 kPa) at air line 2022,

relay spring valve No.1 is OK.

(6) Apply PARKING BRAKE.

(7) Remove gage and connect air hose

2022 to air chamber.

RELAY SPRING VALVE NO. 1 TEST

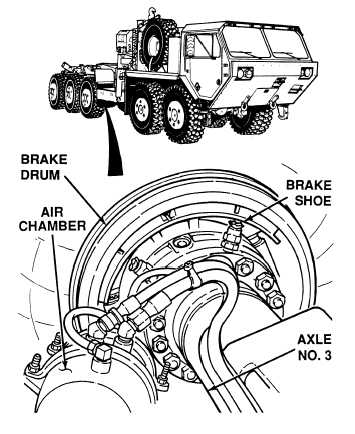

(1) Listen to air chamber while

assistant releases and applies

PARKING BRAKE.

(a) If assistant cannot hear air

chamber operate, or the brake

shoe does not move when

parking brake control is

pushed and pulled, perform

Step (2) below and replace air

chamber (Para 12-10).

(b) If air chamber operates

correctly, air chamber is OK.

(2) Release PARKING BRAKE.

OPERATION TEST

|