|

| |

TM 9-2320-364-20-2

2-1861

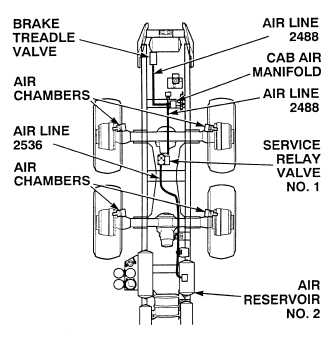

(1) Check air lines 2488 and 2536 for

crimps (see schematic Fig 2-44).

(a) If there are crimps in air lines,

replace air lines (Para 12-36).

(b) If there are no crimps in air lines,

perform Steps (2) and (3) below.

(2) Apply service brakes

(TM 9-2320-364-10).

(3) Check fittings and air lines 2488, 2536

for leaks (see schematic Fig 2-44).

(a) If fittings or air lines are leaking,

perform Step (6) below and

tighten/replace fittings and/or

replace air lines (Para 12-36).

(b) If there are no leaks, fittings and

air lines are OK. Perform

Step (4) below.

(4) Check service relay valve No. 1 for

leaks.

(a) If service relay valve No. 1

leaks, perform Step (6) below

and replace valve (Para 12-13).

(b) If there are no leaks, perform

Step (5) below.

(5) Check air chambers for leaks.

(a) If air chamber leaks, perform

Step (6) below and replace air

chamber (Para 12-9).

(b) If there are no leaks, perform

Step (6) below.

(6) Release service brakes.

VISUAL/AUDIBLE INSPECTION

Wear safety goggles when performing leakage tests on valves. Failure to do so may result in serious eye

injury due to high pressure air.

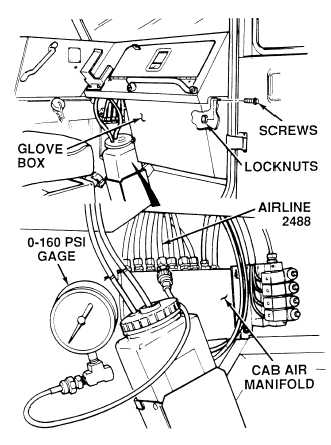

(1) Remove six screws, locknuts and

glove box. Discard locknuts.

(2) Disconnect air line 2488 from cab

air manifold.

(3) Connect 0 to 160 psi (0-1103 kPa)

gage to air line 2488.

(4) Apply service brakes

(TM 9-2320-364-10).

(a) If there are not 125 4 psi

(861 28 kPa) present at air line

2488, perform Steps (5)

through (7) below and replace

brake treadle valve (Para 12-4).

(b) If there are 125 4 psi

(861 28 kPa) present at air line

2488, brake treadle valve is OK.

(5) Release service brakes.

(6) Remove gage and connect air line

2488 to cab air manifold.

(7) Install glove box, six screws and

locknuts.

BRAKE TREADLE VALVE TEST

|