|

| |

TM 9-2320-364-20-2

2-973

(1) Check oil sending units for leakage or

damage.

(a) If oil sending units are loose,

leaking, or damaged, tighten or

replace damaged units

(Para 7-79).

(b) If oil sending units are not leaking,

oil sending units are OK.

(2) Install left side noise panel, eight

screws, washers, and lockwashers.

(3) Install right side noise panel

(Para 17-26).

VISUAL INSPECTION

(1) Start engine (TM 9-2320-364-10).

(2) Scroll down to mode 17 OIL

PRESSURE PSI.

(3) Increase engine speed to 1800 to

2100 RPM.

(a) If engine oil pressure is less than

35 psi (241 kPa), perform Steps

(3) through (5) below and notify

DS Maintenance.

(b) If engine oil pressure is between

35 and 40 psi (241 and 276 kPa),

fault has been corrected.

(3) Clear codes (Para 2-11).

(4) Turn OFF ENGINE switch.

(5) Disconnect DDR from DDL

connector MC13.

VERIFY REPAIR

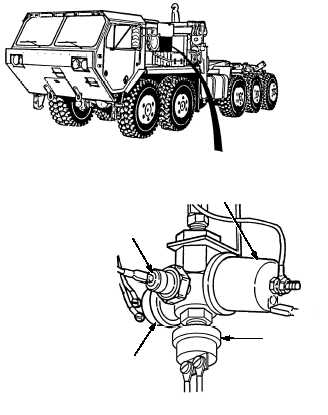

ENGINE OIL

PRESSURE

SENDING UNIT

HOUR METER

SENSOR

ATEC, OIL

PRESSURE

SENSOR

ALT, OIL

PRESSURE

SENSOR (IF

EQUIPPED)

|