|

| |

TM 9-2320-364-20-2

2-1077

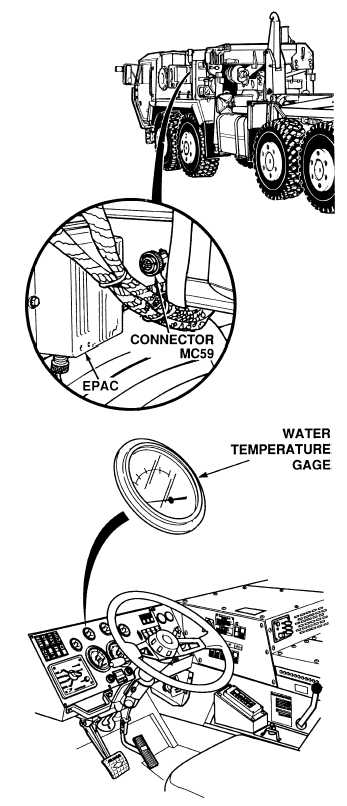

(1) Disconnect harness connector MC59

from EPAC.

(2) Start engine (TM 9-2320-364-10).

(a) If fan speed does not increase,

perform Steps (3) through (6)

below and notify DS Maintenance.

(b) If fan speed does increase,

perform Steps (3) through (5)

below and go to Step 5 of

this Fault.

(3) Turn OFF ENGINE switch.

(4) Install left side noise panel, eight

washers, lockwashers and screws.

(5) Install right side noise panel

(Para 17-26).

(6) Connect harness connector MC59

to EPAC.

FAN TEST

(1) Start engine (TM 9-2320-364-10).

(2) Observe WATER TEMP gage for

reading above 230F (110C) with

engine running and fan at high speed.

(a) If WATER TEMP gage indicates

engine temperature above 230F

(110C), cooling assembly is

faulty. Perform Steps (3) and (4)

below and go to Step 6 of

this Fault.

(b) If WATER TEMP gage indicates

engine temperature under 230F

(110C), temperature sensing

circuit is faulty. Perform Steps (3)

and (4) below and go to Step 10 of

this Fault.

(3) Turn OFF ENGINE switch.

(4) Connect harness connector MC59

to EPAC.

FAN OPERATION/TEMP TEST

Engine temperature must be below

192F (88C) before performing test.

NOTE

Allow engine to cool before performing troubleshooting maintenance. If necessary use insulated pads

and gloves. Hot engine components will burn and cause injury to personnel.

Do not place any part of body in area of fan operation

to personnel.

|