|

| |

TM 9-2320-364-20-2

2-823

(1)

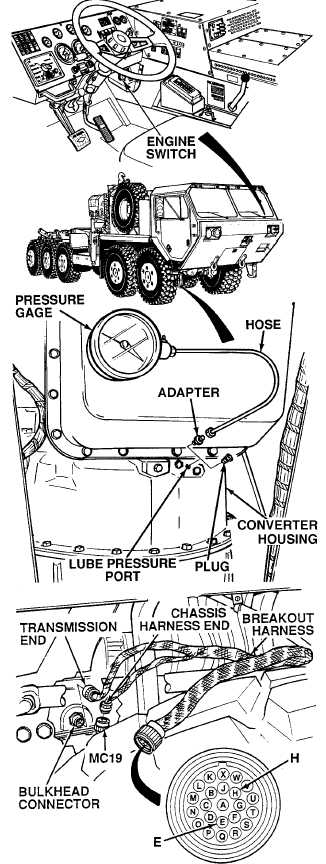

Position suitable container to catch

oil.

(2)

Remove lube port plug from bottom of

torque converter housing.

(3)

Install Test Kit-hose adapter and

direct reading oil pressure 0 to 160 psi

(0 to 1103 kPa) gage in transmission

torque converter housing lube oil

pressure port.

(4)

Set multimeter select switch to ohms.

(5)

Start engine (TM 9-2320-364-10).

(6)

No continuity will be measured

between breakout harness, terminals

E and H at oil level pressure switch

as pressure increases.

(a) If pressure is not correct or

pressure switch is not

functioning correctly, fault is

in transmission. Perform Step

(7) below and notify DS

Maintenance.

(b) If pressure is correct and

pressure switch functions

corrrectly, oil level pressure

switch is OK.

(7)

Turn OFF ENGINE switch.

(8)

Remove oil pressure gage and

Test Kit hose adapter from lube oil port

of transmission torque converter

housing.

(9)

Apply pipe sealant to lube port plug

and install in lube oil port.

(10)

Tighten plug to 4 to 5 lb-ft (5 to 7 N.m).

CONTINUITY TEST

Ensure equipment will not move while

repairing or inspecting it. For trailers,

“red tag” the hitch, and block or chock

wheels or tracks. For powered

equipment, block or chock wheels or

tracks, and “red tag” the starter. Prevent

a “quick fix” from becoming a quick injury.

When adjustment or service requires a

running engine, two personnel will be

used; one at controls and one at service

point. This helps prevent accidental

movement of controls.

NOTE

Approximately one quart of oil will flow from oil

level port when plug is removed. Due to

limited work area, be prepared with suitable

container to catch oil.

|