|

| |

TM 9-2320-364-20-2

2-1769

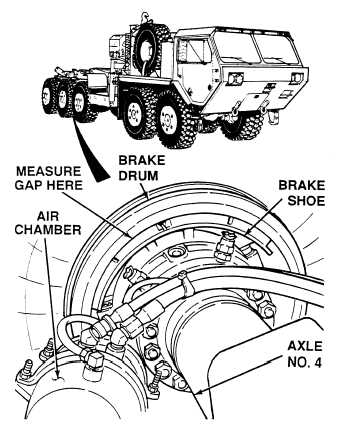

(1) Measure gap between brake shoe and

drum (Para 12-3).

(a) If there is no gap, adjust brakes

(Para 12-3).

(b) If there is a gap, perform Steps

(2) through (5) below.

(2) Cage air chamber (Para 12-10).

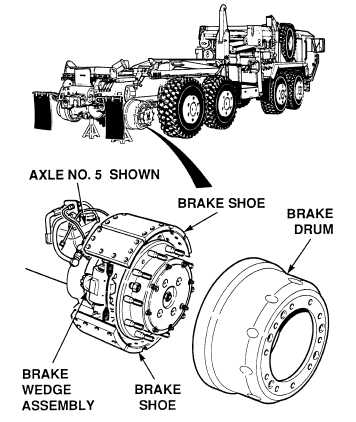

(3) Remove brake drum and air

chamber (Para 13-3 and 12-10).

(4) Inspect brake shoes and wedges

(Para 12-2).

(a) If brake shoes and/or wedges are

faulty, replace brake shoe and/or

wedges (Para 12-2).

(b) If shoes and wedges are OK,

perform Step (5) below and notify

DS Maintenance.

(5) Install brake drum and air chamber

(Para 13-3 and 12-10).

Wear safety goggles when performing

leakage tests on valves. Failure to do

so may result in serious eye injury due

to high pressure air.

Truck must be on level ground and wheels

must be chocked before parking brake is

released. Otherwise, truck may roll and

cause injury to personnel.

(1) Listen to air chamber and observe

brake shoe movement while assistant

releases and applies PARKING

BRAKE (TM 9-2320-364-10).

(a) If assistant cannot hear air

chamber operate or brake shoe

does not move when parking

brake control valve is pushed and

pulled, perform Step (2) below

and replace faulty air chamber

(Para 12-10).

(b) If air chamber operates correctly,

perform Step (2) below and go to

Step 5 of this Fault.

(2) Release PARKING BRAKE.

OPERATION TEST

VISUAL INSPECTION

|