|

| |

TM 9-2320-364-20-3

2-1921

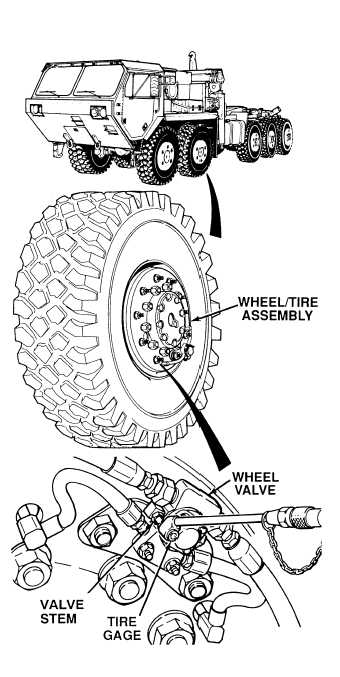

(1) Check wheel valve for air leaks

(a)

If wheel valve is leaking, turn OFF

ENGINE switch and replace

wheel valve (Para 13-11).

(b)

If there are no leaks, wheel valve

is OK.

(2) Turn OFF ENGINE switch.

AUDIBLE/VISUAL INSPECTION

Wear safety goggles when performing leakage tests on valves. Failure to do so may result in serious eye

injury due to high pressure air.

Exercise extreme caution when working around wheels or under truck while engine is operating.

Movement of truck may cause injury or death to personnel.

High air pressure will be released from valve stem when valve core is removed. Stay clear of valve stem after

core is removed. Ensure all personnel wear suitable eye protection. Failure to comply may result in injury to

personnel.

(1) Remove valve cap from valve stem.

(2) Position air pressure gage on

valve stem.

(3) Start engine (TM 9-2320-364-10).

(4) Position CTIS controller to HIGH-

WAY setting.

(5) As assistant presses CTIS start

button, observe air gage.

(a)

If there is no increase in air

pressure, perform Steps (8)

and (9) below and replace

wheel valve (Para 13-11).

(b)

If there is an increase in air

pressure, go to Step (6) below.

(6) Set CTIS controller to CROSS

COUNTRY.

(7) As assistant presses CTIS start

button, observe air gage.

(a)

If there is no decrease in air

pressure, perform Steps (8)

and (9) below and replace

wheel valve (Para 13-11).

(b)

If there is a decrease in air

pressure, wheel valve is OK.

(8) Turn OFF ENGINE switch.

(9) Remove air gage.

(10) Install valve cap on valve stem.

PRESSURE TEST

Some air leakage may occur at breather during

inflation/deflation cycles. Rapid exhaust of air a

breather indicates a faulty valve.

NOTE

|