|

| |

TM 9-2320-364-20-4

12-33

Air chamber can only be turned

out a maximum of one turn.

Failure to comply may result in

damage to equipment.

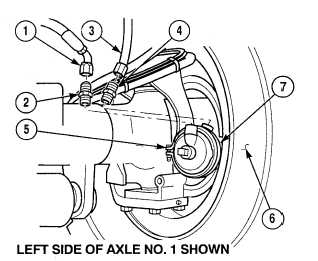

(f)

Rotate air chamber (5) to align air

ports.

Adhesives, solvents, and sealing

compounds can burn easily, can

give off harmful vapors, and are

harmful to skin and clothing. To

avoid injury or death, keep away

from open fire and use in well-

ventilated area. If adhesive,

solvent, or sealing compound gets

on skin or clothing, wash

immediately with soap and water.

(g)

Coat threads of two fittings (2) and (4)

with sealing compound.

(h)

Install fittings (2) and (4) in air chamber (5).

NOTE

Refer to Table 12-1 for air line numbers.

(i)

Install air line (3) on fitting (4).

(j)

Install air line (1) on fitting (2).

(k)

Start truck and build air pressure to 125 psi (861 kPa).

(l)

Turn OFF engine switch.

(m) Release parking brake.

(n)

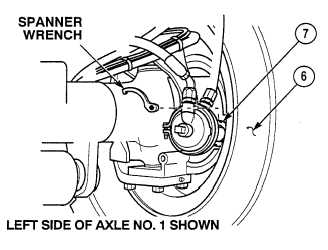

With the aid of an assistant, apply service brake pedal and using spanner wrench tighten collet nut (7)

to 250 to 280 lb-ft (339 to 380 N.m).

(o)

Release brake pedal.

(p)

Push in on brake drum (6) approximately two inches to reinstall brake drum (6).

|