|

| |

TM 9-2320-364-20-5

18-3

Use care when removing

retaining rings. Retaining rings

are under spring tension and can

act as projectiles when released

and could cause severe eye injury.

Bearings may fall from races

upon removal if care is not taken,

and damage to equipment may

result.

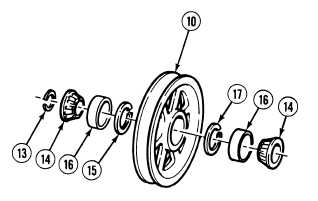

(6)

Remove retaining ring (13), two bearings

(14) and spacer (15) from sheave (10).

NOTE

Perform Step (7) if bushings are

damaged.

(7)

Remove two bushings (16) and retaining ring (17) from sheave (10).

b.

Cleaning/Inspection.

Drycleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles, face

shield, and gloves; use only in a well-ventilated area; avoid contact with skin, eyes, and

clothes, and do not breathe vapors. Keep away from heat or flame. Never smoke when using

solvent. The flashpoint for Type II Drycleaning Solvent is 140 degrees F (60 degrees C) and

Type III Drycleaning Solvent is 200 degrees F (93 degrees C). Failure to do so may result in

injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts

eyes, immediately flush eyes with water and get immediate medical attention.

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with

effective chip guarding and personal protective equipment (goggles/shield, gloves, etc).

Failure to comply may result in injury or death to personnel.

(1)

Clean all metal parts with drycleaning solvent.

(2)

Allow bearing to air dry, then coat with lubricating oil.

(3)

Dry metal parts with compressed air.

(4)

Inspect metal parts for breaks, cracks and sharp edges.

(5)

Inspect bearing for loose rollers or cracked and broken races.

(6)

Replace all damaged parts.

|