|

| |

TM 9-2320-364-20-5

13-7

(4)

Inspect complete inside surface of inner liner for imperfections, discoloration or irregular surface that may

indicate excessive heat, breaks or other fabric damage.

(5)

Check rims for cracks, dents, dirt and rust.

(6)

Remove rust, gummy rubber deposits, nicks and gouges in the rim bead seat surface to provide an airtight

seal with the tire bead.

(7)

Remove all dirt and foreign material from inside of tire and inspect the inside of tire for damage.

(8)

Clean rust and dirt from rim using a steel brush.

(9)

Paint wheel asembly parts as needed to protect against rust.

(10)

Replace any bent, broken, stripped or damaged studs or bolts.

c.

Assembly.

Ensure all personnel keep hands and fingers out from between tire and bead lock. Failure

to comply may result in injury to personnel.

Do not use retread tires on vehicles equipped with a Central Tire Inflation System (CTIS).

Use only the tires that are specified in the Repair Parts and Special Tools List (RPSTL).

Failure to comply may result in tire failure and loss of vehicle control.

NOTE

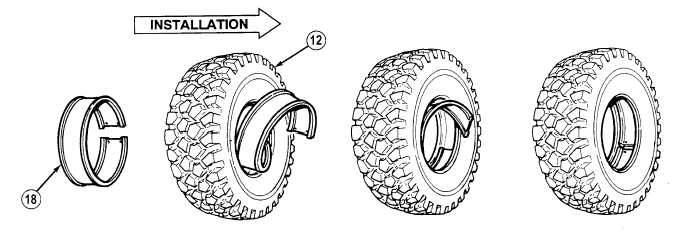

Tire lubricant may be used to ease installation of bead lock in tire.

Curved plate is installed in same direction as curve in bead lock.

(1)

Insert one end of bead lock (18) into tire (12).

(2)

Insert remaining section of bead lock (18) by “cork screwing” into tire (12).

|