|

| |

TM 9-2320-364-20-5

13-9

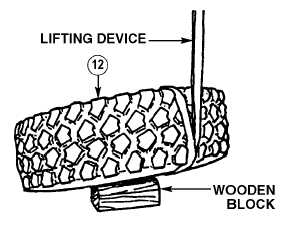

(5)

Attach lifting device to tire (12) and lay tire

on wooden block.

(6)

Remove lifting device from tire (12).

If wheel studs were replaced, they

must be torqued after 50 to 75

miles (80 to 120 km) of use.

Failure to comply may result in

failure of wheel studs.

NOTE

If damaged studs were

removed, perform Step (7).

Ensure flat edge of stud head

is positioned parallel to edge

of inner wheel.

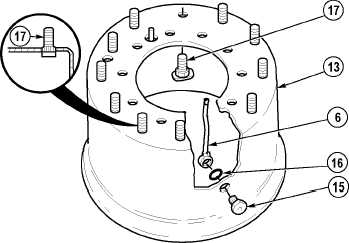

(7)

Install new stud (17) in inner wheel (13)

until base of stud is solid against back side

rim.

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors, and

are harmful to skin and clothing. To avoid injury or death, keep away from open fire and use

in well-ventilated area. If adhesive, solvent, or sealing compound gets on skin or clothing,

wash immediately with soap and water.

(8)

Coat threads of two nuts (15) with sealing compound.

(9)

Install two grommets (16) and valve stems (6) in inner wheel (13) with two nuts (15).

|