|

| |

TM 9-2320-364-34-2

3-183

Materials/Parts - Continued

Locknut (12) (Item 199, Appendix E)

Locknut (2) (Item 200, Appendix E)

Locknut (Item 210, Appendix E)

Lockwasher (4) (Item 286, Appendix E)

Lockwasher (12) (Item 288, Appendix E)

Materials/Parts

Cable Ties (Item 9, Appendix B)

Primer “T” (Item 46, Appendix B)

Sealing Compound (Item 53, Appendix B)

Sealing Compound (Item 56, Appendix B)

Gasket (Item 55, Appendix E)

This task covers:

a. Upper Container Removal

c. Engine Assembly Installation

e. Follow On Maintenance

b. Engine Assembly Removal

Into Container

From Container

d. Upper Container Installation

INITIAL SETUP

Personnel Required

Two

Equipment Condition

Transmission and air compressor removed from

engine, (Para 3-5)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Jackstand (4) (Item 132, Appendix F)

Wrench, Torque (0-175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

Lifting Device, Minimum Capacity 2600 lbs

(1180 kg)

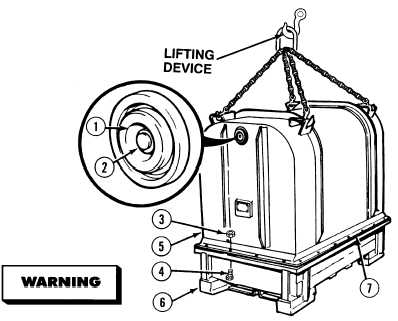

3-33. SHIPPING CONTAINER, ENGINE ASSEMBLY REPLACEMENT.

a.

Upper Container Removal.

Release air pressure prior to

opening container or injury to

personnel could result.

(1)

Release air pressure at breather valve (1) by

pressing air release button (2).

(2)

Remove 26 nuts (3) and screws (4) from

upper and lower container (5) and (6).

Upper container weighs 480 lbs (218 kg). Attach lifting device prior to removal to prevent

injury to personnel.

(3)

With the aid of an assistant, attach lifting device to upper container (5).

(4)

Remove upper container (5) from lower container (6).

(5)

Remove and discard gasket (7) from lower container (6).

(6)

Remove lifting device from upper container (5).

|