|

| |

TM 9-2320-364-34-2

7-17

Materials/Parts

Cloth, Cleaning (Item 11, Appendix B)

Grease (Item 22, Appendix B)

Oil, Hydraulic (Item 34, Appendix B)

Rags, Wiping (Item 47, Appendix B)

Solvent, Drycleaning (Item 68, Appendix B)

Gasket (Item 105, Appendix E)

Gasket (Item 109, Appendix E)

Key (2) (Item 139, Appendix E)

Ring, Seal (Item 507, Appendix E)

Screw (2) (Item 542, Appendix E)

Screw, Self-Locking (30) (Item 555, Appendix E)

Seal Ring (Item 612, Appendix E)

Seal Ring (Item 613, Appendix E)

This task covers:

a. Removal

c. Cleaning/Inspection

e. Installation

b. Disassembly

d. Assembly

f. Follow-On Maintenance

INITIAL SETUP

Personnel Required

Two

Equipment Condition

Transmission separated from engine, (Para 3-5)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Compressor Unit, Air (Item 35 Appendix F)

Gloves, Chemical Oil Protective

(Item 81, Appendix F)

Goggles, Industrial (Item 83, Appendix F)

Gun, Airblow (Item 86, Appendix F)

Lifting Bracket (Item 136, Appendix F)

Pan, Drain 4 gal (Item 144, Appendix F)

Pin, Guide (2) (Item 146, Appendix F)

Puller Kit, Universal, Slide Hammer

(Item 175, Appendix F)

Rule, Steel, Machinist (Item 197, Appendix F)

Wrench, Torque (0-175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

Lifting Device, Minimum Capacity 200 lb

(91 kg)

Wooden Blocks (2) (Appendix C)

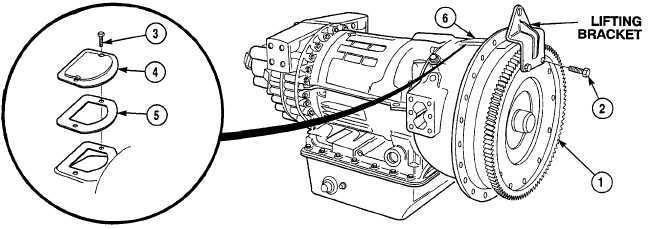

7-10. FLYWHEEL AND TORQUE CONVERTER TURBINE REPAIR.

a.

Removal.

(1)

Position drain pan under flywheel (1).

(2)

Install lifting bracket on flywheel (1) with two screws (2).

(3)

Remove two screws (3), access cover (4) and gasket (5) from converter housing (6). Discard gasket.

|