|

| |

TM 9-2320-364-34-2

8-28

8-5. TRANSFER CASE LUBRICATION PUMP REPLACEMENT (CONT).

b.

Installation.

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors, and

are harmful to skin and clothing. To avoid injury or death, keep away from open fire and use

in a well-ventilated area. If adhesive, solvent, or sealing compound gets on skin or clothing,

wash immediately with soap and water.

(1)

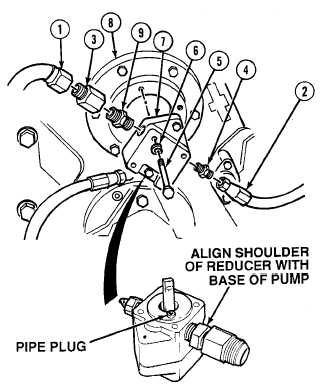

Coat pipe threads of adapters (4) and (9) with sealing compound.

NOTE

Adapters must be installed so flat side of hex shoulder is aligned with base of pump.

(2)

Install adapters (4) and (9) on lubrication pump (7).

(3)

Install reducer (3) in adapter (9).

(4)

Coat threads of four screws (5) with sealing

compound.

NOTE

When installing replacement

lube pump, ensure that pipe plug

has been installed in drive end of

pump.

(5)

Apply sealing compound to bottom lip of

lubrication pump (7).

Ensure spline on shaft engages

with slot on drive plate. Failure

to comply will result in damage

to equipment.

(6)

Install lubrication pump (7) on bearing

cover (8) with four lockwashers (6) and

screws (5). Tighten screws to 168 lb-in (19

N.m).

(7)

Install hose 2815 (1) and hose 2831 (2) on

reducer (3) and adapter (4).

c.

Follow-On Maintenance:

Fill transfer case, (TM 9-2320-364-20).

Start engine, (TM 9-2320-364-10).

LHS in transit position, (TM 9-2320-364-10).

Shut OFF engine, (TM 9-2320-364-10).

Remove wheel chocks, (TM 9-2320-364-10).

END OF TASK

|