|

| |

TM 9-2320-364-34-2

9-2

This task covers:

a. Inspection

b. Follow-On Maintenance

INITIAL SETUP

Personnel Required

Two

Equipment Condition

Engine OFF, (TM 9-2320-364-10)

Wheels chocked, (TM 9-2320-364-10)

Tools and Special Tools

Crowbar (Item 43, Appendix F)

Jack, Hydraulic, Hand (Item 128, Appendix F)

Jackstand (Item 132, Appendix F)

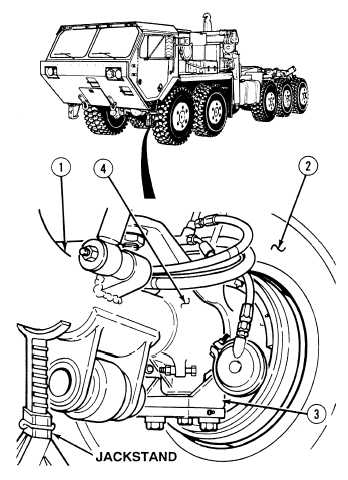

9-2. AXLE NO. 1, 2 AND 5 TRUNNION BEARING INSPECTION.

a.

Inspection.

Axle No. 1 weighs 1950 lbs (885 kg). Use jackstands to support axles. Failure to do so could

result in injury to personnel.

NOTE

Axles No. 1, 2 and 5 are

inspected the same way. Axle

No. 1 is shown.

(1)

Using a hydraulic jack, raise Axle No. 1 (1)

so tire (2) is clear of ground.

(2)

Position jackstand under Axle No. 1 (1) and

lower axle onto jackstand.

(3)

Position crowbar under tire (2).

NOTE

If any wheel play is noticed,

replace trunnion bearing

(Para 9-9).

(4)

With the aid of an assistant, watch for play

at wheel end socket (3) and ball (4) while

prying up on tire (2) with crow bar.

(5)

Raise Axle No. 1 (1) and remove jackstand.

(6)

Lower Axle No. 1 (1) and remove lifting

device.

b.

Follow-On Maintenance:

Remove wheel chocks, (TM 9-2320-364-10).

END OF TASK

|