|

| |

TM 9-2320-364-34-2

9-111

b.

Installation.

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors, and

are harmful to skin and clothing. To avoid injury or death, keep away from open fire and use

in well-ventilated area. If adhesive, solvent, or sealing compound gets on skin or clothing,

wash immediately with soap and water.

(1)

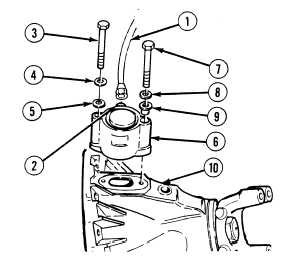

Coat mating surface of differential (10) with adhesive.

(2)

Position locking cylinder (6) on differential (10).

(3)

Position plastic washer (9), washer (8) and screw (7) on locking cylinder (6).

NOTE

Install screw only to keep screw

hole in locking cylinder aligned

with differential. Screw should

be positioned so that three or four

threads of screw are engaged.

(4)

Position washer (4) and screw (3) on

locking cylinder (6).

(5)

Tighten screw (7) on locking cylinder (6) to

22 to 32 lb-ft (30 to 43 N.m).

(6)

Install air line 2419 (Axle No. 1) (1) to

fitting (2).

c.

Adjustment.

NOTE

Perform adjustment only if a new

locking cylinder was installed or

axle differential was removed.

(1)

Remove wheel chocks.

(2)

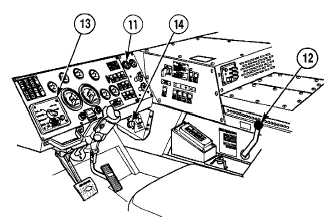

Start engine and build up air pressure (11)

to 125 psi (862 kPa).

(3)

Shift transfer case (12) to low.

(4)

Switch CTIS controller (13) to

EMERGENCY.

(5)

Drive truck forward or backward five ft

(1.5 m).

(6)

Turn OFF engine switch (14).

(7)

Chock wheels.

|