|

| |

TM 9-2320-364-34-2

10-24

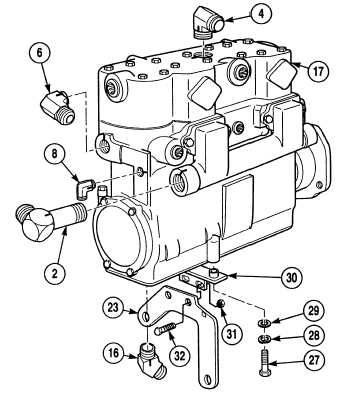

10-4. AIR COMPRESSOR REPLACEMENT (CONT).

(3)

Install bracket (30) on air compressor

mounting bracket (23) with two screws (32)

and locknuts (31).

(4)

Install bracket (30), two washers (29),

lockwashers (28) and screws (27) in air

compressor (17).

Adhesives, solvents, and sealing

compounds can burn easily, can

give off harmful vapors, and are

harmful to skin and clothing. To

avoid injury or death, keep away

from open fire and use in a well-

ventilated area. If adhesive,

solvent, or sealing compound

gets on skin or clothing, wash

immediately with soap and

water.

(5)

Apply sealing compound to elbows (2), (4),

(6), (8) and (16).

(6)

Install elbows (2), (4), (6), (8) and (16) in

air compressor (17).

(7)

Apply grease to gasket (26) and install on air

compressor (17).

Air compressor weighs 115 lbs

(52 kg). Attach suitable lifting

device prior to installation to

prevent possible injury.

(8)

Attach lifting device to air compressor (17).

(9)

Install drive coupling (25) on air

compressor (17).

(10)

Align drive coupling (25) in engine (24).

(11)

Install air compressor (17) on engine (24).

(12)

Install two lockwashers (22) and screws

(21) in air compressor mounting bracket

(23). Tighten screws to 80 lb-ft (108 N.m).

|