|

| |

TM 9-2320-364-34-3

14-19

Force required to remove beam end bushings and beam center bushing may exceed 30 tons (27

metric tons). Use a press of 60-ton (54 metric tons) capacity or more to remove and install

bushings. Use care when pressing out bushings to prevent serious personal injury or death.

Always wear eye protection to prevent injury when operating press.

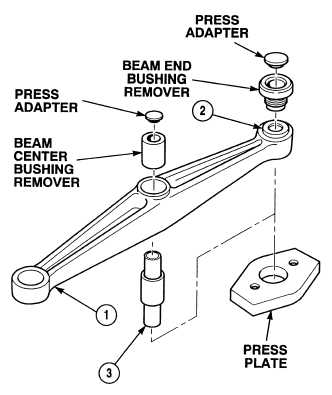

Ensure beam end bushing remover is correctly aligned on the bushing shell before

attempting start pressing operation. Also check that equalizer beam is correctly aligned on

press plate so that there is clearance for old beam end bushing to drop through.

(3)

Using beam end bushing remover and press

adapter, press beam end bushing (2) out of

equalizer beam (1). Discard beam end

bushing.

(4)

Repeat Steps (1) through (3) for other beam

end bushing (2).

(5)

Inspect outer edge of beam center

bushing (3). If outer edge of beam center

bushing is “mushroomed” over face of

equalizer beam (1), chisel or file

mushroomed steel away.

NOTE

Center bushing remover tools for

front and rear equalizer beams are

very similar. Use larger diameter

remover for rear beams and smaller

diameter remover for front beams.

(6)

Using beam center bushing remover and

press adapter, press beam center bushing (3)

out of equalizer beam (1). Discard beam

center bushing.

c.

Cleaning/Inspection.

Drycleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles, face

shield, and gloves; use only in a well-ventilated area; avoid contact with skin, eyes, and

clothes, and do not breathe vapors. Keep away from heat or flame. Never smoke when

using solvent. The flashpoint for Type II Drycleaning Solvent is 140 degrees F (60 degrees

C) and Type III Drycleaning Solvent is 200 degrees F (93 degrees C). Failure to do so may

result in injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts

eyes, immediately flush eyes with water and get immediate medical attention.

(1)

Clean equalizer beam with drycleaning solvent.

|