|

| |

TM 9-2320-364-34-3

14-33

Corrosion preventive compound contains alkali. Do not get in eyes. Wear goggles/safety

glasses when using. Avoid contact with skin. In case of contact, immediately wash area with

soap and water. If eyes are contacted, flush eyes with large amounts of water for at least 15

minutes and get immediate medical attention.

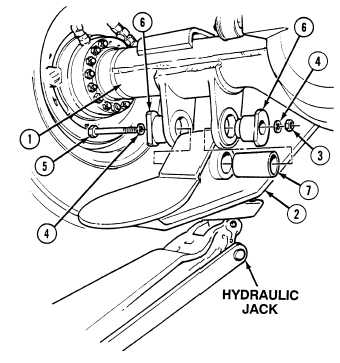

(11)

Coat outside diameter of spacer (7) and two

adapters (6) with corrosion preventive

compound.

(12)

Install spacer (7) in trailing beam (2).

The trailing beam weighs 150 lbs

(68 kg). Use a hydraulic jack to

support axle end of trailing beam

prior to installation to prevent

possible injury to personnel.

NOTE

The following step may require

use of a soft faced hammer to

position trailing beam.

(13)

With the aid of an assistant and a hydraulic

jack, position trailing beam (2) on axle

end (1).

(14)

Install two adapters (6) in trailing beam (2).

(15)

Apply lubricating oil to threads of screw (5).

(16)

With the aid of an assistant, install

washer (4), screw (5), washer (4) and

locknut (3) on trailing beam (2). Tighten

locknut to 210 to 240 lb-ft (285 to 325 N.m).

(17)

Remove hydraulic jack from trailing

beam (2).

f.

Follow-On Maintenance:

Install axle air bag, (Para 14-4).

Install stowage box and stowage box bracket, (TM 9-2320-364-20) (right trailing beam).

Align/adjust steering system, (Para 12-8).

Tighten fuel tank straps, (TM 9-2320-364-20).

Remove wheel chocks, (TM 9-2320-364-10).

END OF TASK

|