|

| |

TM 9-2320-364-34-4

20-136

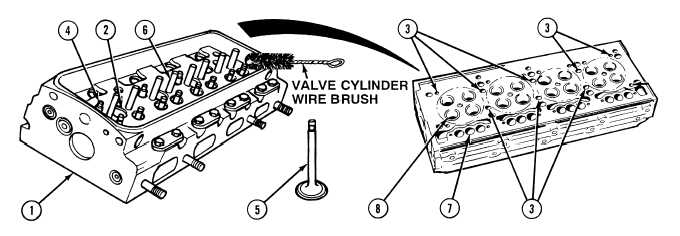

20-49. CYLINDER HEAD REPAIR (CONT).

(10)

Inspect eight injector tubes (2) for scoring, cracking, and leaks. If injector tubes fail inspection, replace

injector tubes.

(11)

Inspect eight water nozzles (3) for looseness or damage. Replace water nozzles failing inspection or

leakage during pressure testing.

(12)

Inspect 16 valve guides (4) for cracks, chipping, scoring, or excessive wear.

(13)

Using valve cylinder wire brush, clean valve guides (4).

NOTE

Inside diameter of valve guide must be minimum of 0.3125 in. (7.938 mm) and maximum

of 0.3140 in. (7.9756 mm).

Outside diameter of valve stem must be minimum of 0.310 in. (7.874 mm) and maximum

of 0.309 in. (7.849 mm).

(14)

Measure inside diameter of valve guide (4).

(15)

Measure outside diameter of corresponding valve stem (5).

NOTE

To obtain valve guide clearance, subtract valve stem diameter from valve guide inside

diameter measurement. Clearance should be between minimum of 0.0017 in. (0.0432 mm)

and maximum of 0.0035 in. (0.0889 mm), with limit of 0.0050 in. (0.1270 mm).

(16)

Determine valve guide clearance. If valve guide has excessive clearance or inside diameter, replace

valve guide.

(17)

Inspect valve bridge guides (6) for cracks, chipping, scoring, or excessive wear. If valve bridge guides

fail inspection, replace valve bridge guides.

|