|

| |

TM 9-2320-364-34-4

20-138

20-49. CYLINDER HEAD REPAIR (CONT).

c.

Pressure Testing.

NOTE

Perform magnetic particle and fluorescent penetrant inspections before pressure testing.

These inspections will locate exterior cracks. Replace cylinder head if cracks are detected.

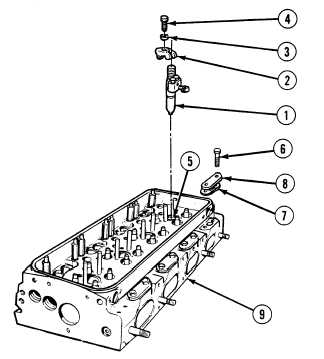

(1)

Install four injectors (1) (removed in Para

4-2) with clamps (2), washers (3) and

screws (4) in injector tubes (5). Tighten

screws 20 to 25 lb-ft (27 to 34 N.m).

Adhesives, solvents, and sealing

compounds can burn easily, can

give off harmful vapors, and are

harmful to skin and clothing. To

avoid injury or death, keep away

from open fire and use in well-

ventilated area. If adhesive,

solvent, or sealing compound

gets on skin or clothing, wash

immediately with soap and

water.

(2)

Apply coat of sealing compound to threads

of eight screws (6).

(3)

Install four gaskets (7) and covers (8) on

cylinder head (9) with eight screws (6).

Tighten to 26 to 29 lb-ft (35 to 39 N.m).

(4)

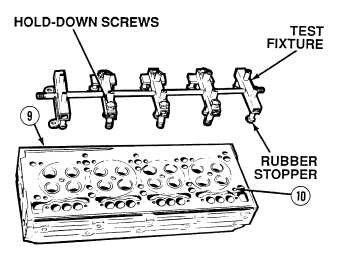

Align test fixture on top of bottom face of

cylinder head (9) so rubber stoppers cover

water inlets (10).

Do not overtighten hold-down

cap screws. Rubber stopper

could distort enough to seal off

outer diameter of water nozzle.

Leak would not be detected from

outer diameter.

(5)

Install and tighten six hold down screws on

test fixture until rubber stoppers start to

flatten out.

|