|

| |

TM 9-2320-364-34-4

20-167

Materials/Parts

Oil, Lubricating (Item 36, Appendix B)

Rope, 3/4 in. thick, 20 ft (Item 48, Appendix B)

Solvent, Drycleaning (Item 68, Appendix B)

Screw (6) (Item 525, Appendix E)

This task covers:

a. Disassembly

b. Cleaning/Inspection

c. Assembly

INITIAL SETUP

Equipment Condition

Idler gear on clean work surface.

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Caps, Vise Jaw (Item 27, Appendix F)

Compressor Unit, Air (Item 35, Appendix F)

Gloves, Chemical Oil Protective

(Item 81, Appendix F)

Goggles, Industrial (Item 83, Appendix F)

Gun, Airblow (Item 86, Appendix F)

Plate Kit, Gear Bearing (Item 148, Appendix F)

Press, 60 Ton (Item 164, Appendix F)

Scale, Tension (Item 199, Appendix F)

Vise, Machinist’s (Item 248, Appendix F)

Wrench, Torque (0-175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

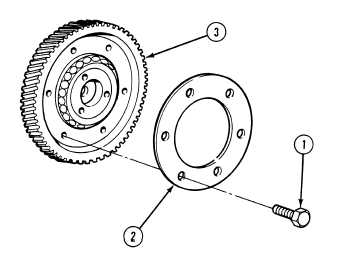

20-58. IDLER GEAR REPAIR.

a.

Disassembly.

NOTE

Perform this task for DDEC II

engines only.

If DDEC III idler gear is

damaged, it must be replaced.

The idler gear bearing is a

matched assembly. Matchmark

components during disassembly

to ensure reassembly of the parts

in their original positions.

(1)

Remove and discard six screws (1) from

retainer (2).

(2)

Remove retainer (2) from idler gear (3).

|