|

| |

TM 9-2320-364-34-4

20-186

20-60. PISTON AND CONNECTING ROD REPAIR (CONT).

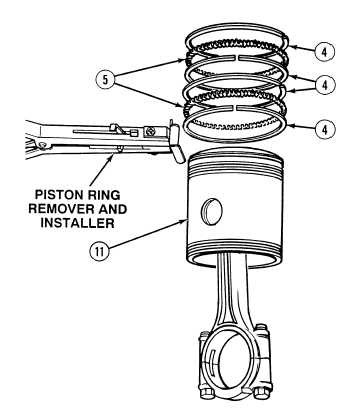

To prevent damage to oil rings

when piston is installed in ring

compressor, make sure ends of

expander rings do not overlap.

(25)

Lubricate two oil ring expanders (5) with

lubricating oil.

NOTE

Two oil ring expanders are

installed with ends pointing

upward and are positioned 180

degrees apart.

(26)

Install two oil ring expanders (5) on piston

skirt (11).

NOTE

Install oil rings with beveled edge

facing upward.

(27)

Lubricate chrome, nonslotted oil ring (4)

with lubricating oil.

Use care when installing piston rings. Piston rings are under tension and can act as

projectiles when released and could cause severe eye injury.

NOTE

Chrome, non slotted oil ring is installed with gap position 180 degrees from gap in oil ring

expanders installed in Step (26).

(28)

Using piston ring remover and installer, install chrome, non slotted oil ring (4) in piston skirt (11).

(29)

Lubricate nonslotted oil ring (4) with lubricating oil.

NOTE

Nonslotted oil ring is installed with gap positioned 90 degrees from gap in oil ring installed

in Step (28).

(30)

Using piston ring remover and installer, install nonslotted oil ring (4) in piston skirt (11).

(31)

Lubricate oil ring (4) with lubricating oil.

NOTE

Oil ring is installed with black slotted bottom down and gap positioned 180 degrees from

gap in expander ring installed in Step (26).

(32)

Using piston ring remover and installer, install oil ring (4) in piston skirt (11).

|