|

| |

TM 9-2320-364-34-4

20-192

20-61. CYLINDER LINER REPAIR (CONT).

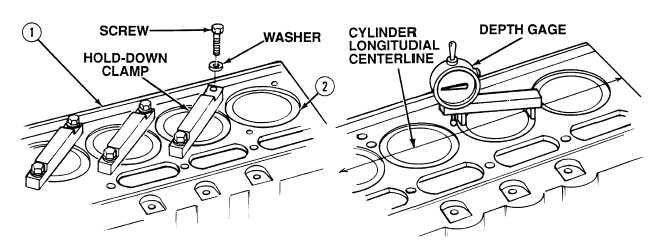

c.

Cylinder Liner Protrusion.

(1)

Install eight hold-down clamps on engine block with 16 washers and screws. Tighten screws to 50 lb-ft

(68 N.m).

(2)

Place depth gage on engine block (1) and set to zero.

NOTE

Although cylinder liners are within specifications, there must not be over 0.0015 in.

(0.0381 mm) difference between any two adjacent cylinder liners when measured along

cylinder longitudinal centerline.

Replace cylinder liner if any measurement exceeds specification.

(3)

Measure distance from top of cylinder liner (2) to top of engine block (1) with depth gage. Depth of

flange below engine block (1) must be minimum of 0.0418 in. (1.0617 mm) and maximum of 0.0482 in.

(1.2243 mm).

(4)

Once cylinder liner (2) is within specifications, tag and mark cylinder liner (2) and engine block (1) so

liner is installed in correct cylinder block bore.

(5)

Remove screws, washers, hold down clamps, and liners (2) from engine block (1).

END OF TASK

|