|

| |

TM 9-2320-364-34-4

20-210

20-64. ENGINE CYLINDER BLOCK REPAIR (CONT).

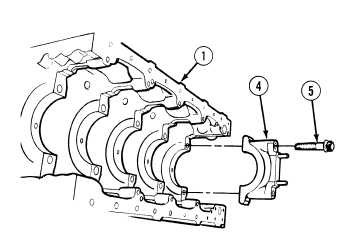

NOTE

Main bearing caps must be

installed in proper positions in

engine block, as marked during

removal. Ensure caps are firmly

seated in engine block and main

bearing shells are removed.

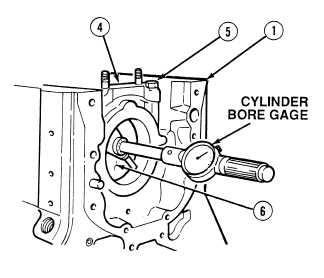

(5)

Position five main bearing caps (4) and ten

screws (5) in engine block (1).

(6)

Tighten screws (5) on bearing caps (4).

(7)

Strike caps (4) with soft-face hammer to

seat them.

(8)

Tighten screws (5) on bearing caps (4) to 50

lb-ft (68 N.m).

(9)

Tighten screws (5) on bearing caps (4) to

110 lb-ft (149 N.m).

(10)

Tighten screws (5) 250 to 260 lb-ft

(339 to 353 N.m).

(11)

Using bore dial gage, measure each main

bearing bore (6) diameter. If main bearing

bore (6) diameter is less than 4.812 in.

(122.225 mm) or is greater than 4.813 in.

(122.250 mm), replace engine block (1).

(12)

Remove screws (5) and five main bearing

caps (4) from engine block (1).

|