|

| |

TM 9-2320-364-34-4

20-213

(19)

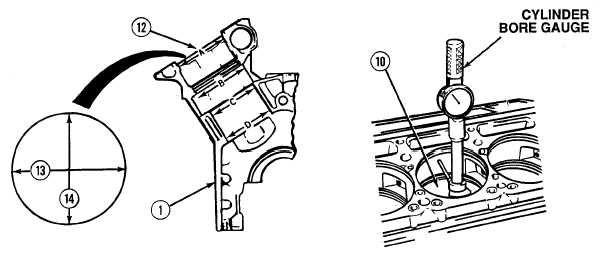

Make two cylinder bore (12) measurements (13) and (14) with cylinder bore gage in Steps (20)

through (23).

(20)

Measure cylinder bore (12) at position A. Measurement cannot be greater than 5.3625 in. (136.2075

mm).

(21)

Measure cylinder bore (12) at position B. Measurement cannot be greater than 5.3395 in. (135.6233 mm).

(22)

Measure cylinder bore (12) at position C. Measurement cannot be greater than 5.2185 in. (132.5499 mm).

(23)

Measure cylinder bore (12) at position D. Measurement cannot be greater than 5.2185 in. (132.5499 mm).

(24)

Maximum out-of-roundness is 0.0010 in. (0.0254 mm).

(25)

Maximum taper is 0.0010 in. (0.0254 mm).

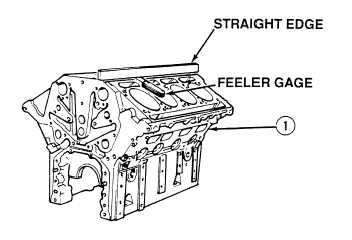

NOTE

Replace engine block (1) if

any cylinder bore is not

within limits.

Lengthwise measurements

must not exceed 0.007 in.

(0.178 mm). Diagonal

measurements must not

exceed 0.003 in.

(0.076 mm).

(26)

Measure top of cylinder head surface on

engine block (1) lengthwise and diagonally

for flatness using a straight edge and feeler

gage.

|