|

| |

TM 9-2320-364-34-4

20-266

Materials/Parts

Lockwasher (6) (Item 292, Appendix E)

Shim (2) (Item 632, Appendix E)

Shim (2) (Item 633, Appendix E)

Shim (2) (Item 634, Appendix E)

This task covers:

a. Installation

b. Follow-On Maintenance

INITIAL SETUP

Equipment Condition

Flywheel housing and rear oil seal installed,

(Para 20-76)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Indicator, Dial, Set w/Magnetic Base

(Item 98, Appendix F)

Wrench, Crowsfoot, 9/16 in., 3/8 in. Drive

(Item 269, Appendix F)

Wrench Set, Socket 3/8 in. Drive

(Item 273, Appendix F)

Wrench, Torque (0 to 60 N.m)

(Item 276, Appendix F)

Wrench, Torque (0 to 175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

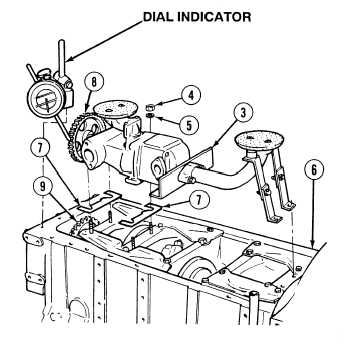

20-77. ENGINE OIL PUMP ASSEMBLY INSTALLATION.

a.

Installation.

NOTE

If shims were damaged during

removal, ensure shims of same

thickness as recorded during

removal are used for installation.

(1)

Install shims (7) on studs in engine

block (6).

(2)

Position oil pump (3) on engine block (6).

(3)

Install four lockwashers (5) and nuts (4) on

studs in engine block (6). Tighten nuts to

27 lb-ft (37 N.m).

NOTE

Each 0.005 in. (0.127 mm)

shim changes gear backlash

0.0035 in. (0.088 mm).

Backlash should be 0.006 to

0.012 in. (0.152 to 0.30 mm).

(4)

Using a dial indicator, measure backlash

between crankshaft oil pump drive gear (8)

and oil pump drive gear (9). Add or

subtract same thickness of shims (7) under

pump to obtain correct backlash.

|