|

| |

TM 9-2320-364-34-4

22-9

(20)

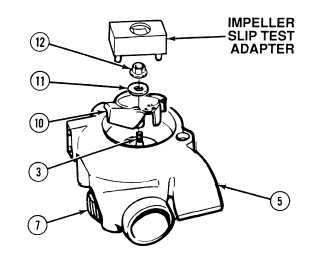

Position pump body (5) in soft jawed vise.

(21)

Position impeller (10) on shaft (3).

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors, and

are harmful to skin and clothing. To avoid injury or death, keep away from open fire and use

in well-ventilated area. If adhesive, solvent, or sealing compound gets on skin or clothing,

wash immediately with soap and water.

Ensure International Compound No. 2 is applied only to threads of shaft. Impeller

slippage may occur if International Compound No. 2 contacts shaft.

Ensure all parts are free of dirt, metal, and oil. If parts are dirty, impeller slippage may

occur.

(22)

Apply International Compound No. 2 to

threads of shaft (3).

(23)

Install washer (11) and locknut (12) on

shaft (3). Tighten locknut to 35 to 40 lb-ft

(47 to 54 N.m).

(24)

Mark line across water pump gear (7) and

shaft (3).

(25)

Mark second line across impeller (10),

locknut (12) and shaft (3).

(26)

Attach water pump impeller slip test

adapter on torque wrench.

(27)

Install impeller slip test adapter dowel pins

in impeller puller holes, and tighten to 80

lb-ft (108 N.m).

(28)

If slippage is noted, remove pump body (5)

from vise and examine scribe marks to

determine if gear (7) has moved or if

impeller (10) has moved.

(29)

If gear (7) has slipped, replace water pump

gear and shaft.

(30)

If impeller (10) has slipped replace shaft.

|