|

| |

TM 9-2320-364-34-4

23-77

(6)

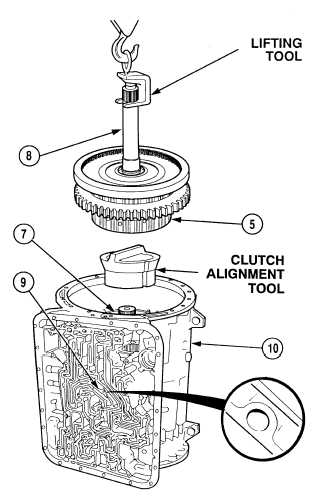

Using alignment tool, compressed air

regulated to a maximum of 40 psi (276 kPa),

and controllable rubber tip safety blowgun,

align fifth clutch plates as follows:

(a)

Install clutch alignment tool on fifth

clutch assembly (7) to align

internal-splined fifth clutch plates. To

fully seat alignment tool, turn back

and forth gently until tool falls in

place.

(b)

Attach lifting tool to turbine shaft (8).

NOTE

Assistant must apply constant

pressure until forward clutch

assembly is installed in

transmission.

(c)

With the aid of an assistant, position

safety blowgun in fifth clutch oil

port (9) located in center of valve

body mounting area.

(d)

Apply 40 psi (276 kPa) maximum air

pressure through oil port (9) to lock

clutch plates.

(e)

Remove clutch alignment tool from

fifth clutch assembly (7).

Forward clutch and turbine shaft

assembly weighs 67 lbs (30 kg).

Attach suitable lifting device for

installation to prevent possible

injury to personnel.

(7)

Autach lifting tool to turbine shaft (8).

(8)

With the aid of an assistant, apply air and

install forward clutch assembly (5) in

transmission housing (10).

(9)

Release air and remove lifting device and

lifting tool from turbine shaft (8).

f.

Follow-On Maintenance:

Install torque converter housing,

(Para 23-12).

END OF TASK

|