|

| |

TM 9-2320-364-34-4

23-88

23-15. FOURTH CLUTCH REPAIR (CONT).

b.

Cleaning/Inspection.

Drycleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles, face

shield, and gloves; use only in a well-ventilated area; avoid contact with skin, eyes, and

clothes, and do not breathe vapors. Keep away from heat or flame. Never smoke when

using solvent. The flashpoint for Type II Drycleaning Solvent is 140 degrees F (60 degrees

C) and Type III Drycleaning Solvent is 200 degrees F (93 degrees C). Failure to do so may

result in injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts

eyes, immediately flush eyes with water and get immediate medical attention.

(1)

Clean all parts with drycleaning solvent and inspect for damage.

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with

effective chip guarding and personal protective equipment (goggles/shield, gloves, etc) to

prevent personal injury.

(2)

Dry all parts with compressed air.

(3)

Inspect retaining ring for nicks and distortion. Retaining ring must snap tight in its groove for proper

functioning. Replace retaining ring if defective.

(4)

Inspect internal-splined plates for embedded metal particles, severely pitted faces, cracks, distortion, and

damaged or missing spline teeth. Remove burrs using soft honing stone. Replace defective plates.

(5)

Discard internal-splined plates if oil groove is not visible.

(6)

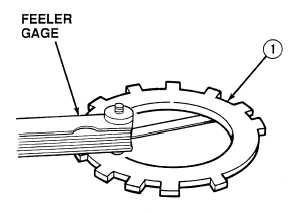

Inspect external-tanged plates (1) for

scoring, cone distortion, imbedded metal

particles, galling, cracks, breaks, and

damaged or missing tangs. Remove burrs

and minor surface irregularities using soft

honing stone. Replace defective plates.

(7)

Measure clearance between inside diameter

of each external-tanged plate (1) and level

surface to determine cone. Discard plates

having clearance in excess of 0.013 in.

(0.330 mm).

|