|

| |

TM 9-2320-364-34-4

25-58

Materials/Parts

Adhesive (Item 1, Appendix B)

Grease (Item 22, Appendix B)

Oil, Lubricating (Item 36, Appendix B)

Sealing Compound (Item 56, Appendix B)

Fitting, Grease (2) (Item 49, Appendix E)

Nut, Adjusting (Item 307, Appendix E)

Packing, Preformed (Item 402, Appendix E)

Seal, Oil (Item 598, Appendix E)

This task covers:

a. Removal

b. Installation

c. Follow-On Maintenance

INITIAL SETUP

Personnel Required

Two

Equipment Condition

Constant velocity joint removed, (Para 25-13)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Gage, Depth, Micrometer (Item 73, Appendix F)

Micrometer, Outside, Caliper, Set

(Item 139, Appendix F)

Multiplier, Torque (Item 141, Appendix F)

Press, 60 Ton (Item 164, Appendix F)

Puller Kit, Universal, Slide Hammer

(Item 175, Appendix F)

Socket, 63 mm (Item 218, Appendix F)

Wrench Set, Socket, 3/4 in. Drive

(Item 274, Appendix F)

Wrench, Torque (0 to 175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

Wrench, Torque (0 to 600 lb-ft [0-814 N.m])

(Item 278, Appendix F)

Holder, Flange (Appendix C)

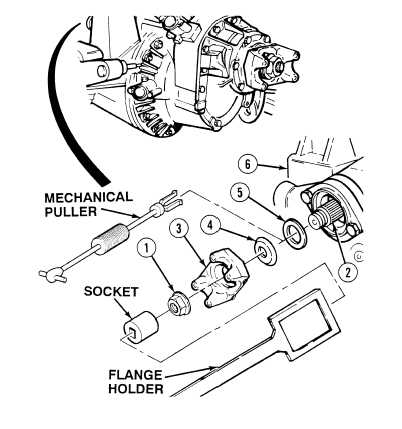

25-14. AXLE NO. 2 REAR OUTPUT ASSEMBLY REPLACEMENT.

a.

Removal.

(1)

Unstake adjusting nut (1).

(2)

With the aid of an assistant, and using

holder and socket, remove adjusting nut

from output shaft (2). Discard adjusting

(3)

Remove flange assembly (3) from pinion

shaft (2).

(4)

Separate dust cover (4) from flange

assembly (3).

(5)

Using puller, remove oil seal (5) from

housing (6). Discard oil seal.

|