|

| |

TM 9-2320-364-34-4

26-7

(3)

Clean interior air and water passages and blow out passages with compressed air.

(4)

Remove any residual gasket material from mating surfaces.

(5)

Inspect cylinder head, cylinder block and crankcase for cracks, gouges and stripped threads.

(6)

Inspect intake valves for wear, grooves, cracks or pits.

(7)

Inspect pistons for scoring, glazing and cracks.

(8)

Inspect cylinder bores for scratches, scoring and pitting.

(9)

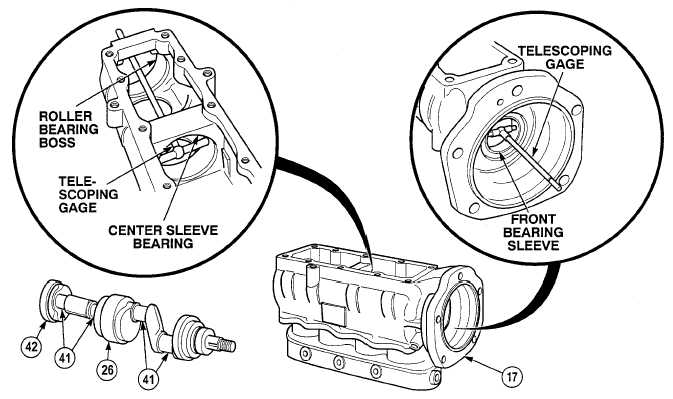

Measure inside diameter of front bearing sleeve. If measurement is not between 2.0026 in. and 2.0036 in.

(50.8660 and 50.8914 mm), replace crankcase.

(10)

Measure inside diameter of center sleeve bearing. If measurement in not between 3.5163 in. and 3.5178 in.

(89.3140 and 89.3521 mm), replace crankcase.

(11)

Visually inspect roller bearing boss for scoring, pitting and cracks.

(12)

Inspect crankshaft (26) for scoring, pitting and cracks.

(13)

Visually inspect crankshaft journals (41) for scoring, pitting and cracks.

(14)

Check ball bearings (42) for wear. Rotate bearings by hand to detect binding. If binding is evident, replace

crankcase (17).

|